Woking table length: 2m Drum width: 1700mm Drum diameter: 210mm Voltage: 220V 1 phase, 220V 3 phase and 380V 3 phase Functions: Automatic shutdown, automatic pneumatic pressure, etc.

US$5500-US$6500

Features

A oil drum heat transfer machine is a machine used to transfer designs onto cut panels or rolls of fabric using heat and pressure. It allows for high-quality and durable transfers onto these products. The machine typically consists of a heated drum and a belt, which applies heat and pressure to the transfer materials. It doesn't have length transfer limitation.

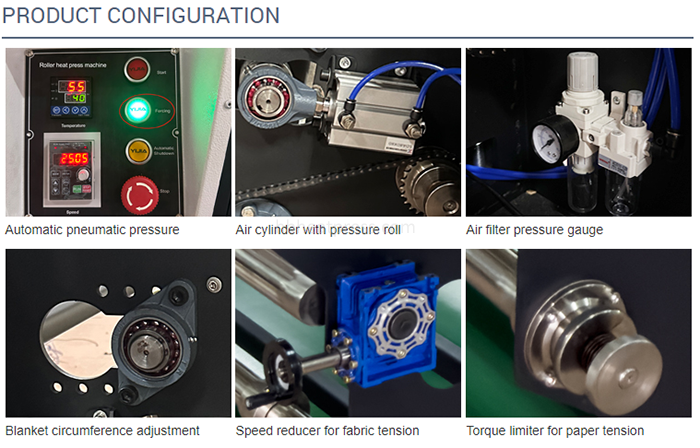

From the control panel, you can see it has a "forcing" button. It can control the air cylinder, so we call it automatic pneumatic pressure.

For sublimating most fabrics, especially thin fabrics need bigger pressure, an air compressor needs to be connected for the calandra. So the air filter pressure gauge can be pulled up and turned to adjust pressure.

Move the roll can adjust blanket circumference when it becomes loose.

Fabric tension can be changed by turning the speed reducer's hand wheel. Change the paper tension by turning the torque limiter.

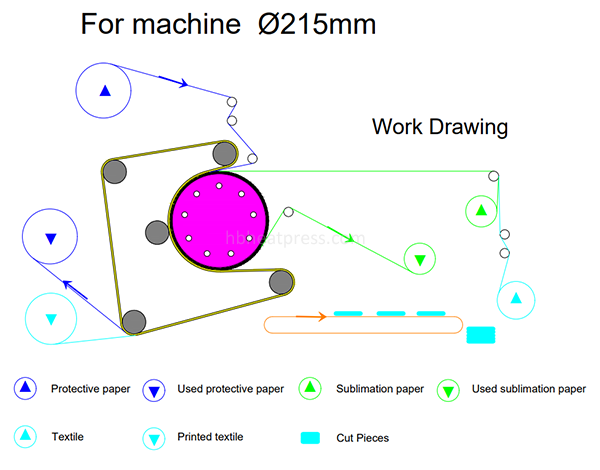

The holder on the green belt is for putting on used sublimation paper roll. When the used sublimation paper roll needs to be removed from the air shaft, it can be put on the holder firstly and help the user remove it.

Printed fabric can be taken up at the back side of the calandra by the roller.

The air shaft helps the user easier take up used paper.

Technical parameters

Item | Data |

Drum type | Chrome-plated |

Drum diameter | 215mm |

Drum width | 1700mm (other drum widths are available) |

Temperature range | 0-260℃ |

Control | Button control |

Total power | 10.6KW |

Main motor power | 0.4KW |

Heat transfer power | 7.4KW |

Automatic shutdown | Yes |

Automatic blanket alignment | Yes |

Adjustable blanket length | Yes |

Automatic pneumatic pressure | Yes |

Heating type | Thermal oil heating |

Voltage | 220V 1 phase/220V 3 phase/380V 3 phase |

Number of air shaft | 1 |

Working way | Roll to roll, roll to pieces, pieces to pieces |

Packing dimension | 245x101x158cm |

Working flow

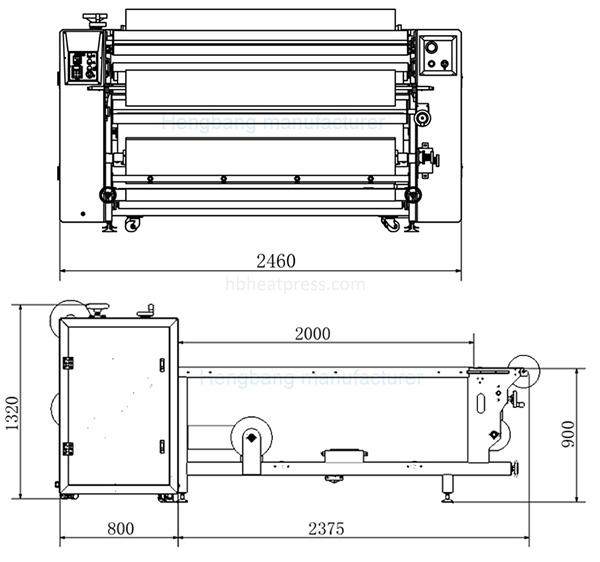

Sublimation calandra dimension

Quality control for roll heat press

How to choose a suitable calander sublimation

How to maintain the roll heat press

Contact: Yina Liu

Phone: +8613424008477

Tel: +8613424008477

Email: info@hbheatpress.com

Add: No.1, Lane 1, Liuyang street, Baisha, Zhongluotan, Baiyun district, Guangzhou, China

We chat