Drum diameter: 210mm Drum width: 1.8m Voltage: 220V 1 phase, 220V 3 phase and 380V 3 phase Sublimation speed: 35-50 meters per hour Heating type: Oil heating

Features

It is usually used in the printing of clothing and textile fabrics, such as knitted fabrics, cloths, tablecloths, scarves, lanyards, cushions, mouse pads and other daily necessities.

The short workbench and compact footprint of this rotary drum heat press calander make it a popular choice for customers from Latin American countries, particularly those with limited space.

In addition, its design, which makes use of a thick frame, shaft, rod, etc., is another factor in its appeal.

It is easier to operate than many plainly constructed roller machines with a 210mm diameter since the paper loading shaft includes a torque for tightening, a reduction for fabric tightening, and other features.

In particular, the pneumatic pressure function that operates automatically and guarantees ideal transfer effects across all fabrics.

It is equipped with two air-expanding shafts as standard. Compared with ordinary optical shafts, it is simple. When loading paper, there is no need to take out the shaft sleeve on one side. After loading the paper, there is no need to replace the shaft sleeve and locking screw. , it only needs to be loaded with paper, point the air gun at the air nozzle and inflate, it will be fully inflated in a few seconds, so that the paper will not move.

It also has an automatic correction system. If the blanket goes astray, the system's motors, photoelectric switches, etc. will start working and control the blanket to move to the center.

Generally, there are five sizes available: 1.2 m, 1.3 m, 1.7 m, 1.8 m, and 1.9 m. Purchasing a machine with a 1.8-meter drum width is necessary if the maximum transfer width falls within the range of 1.6 to 1.65 meters.

165–190°C is the standard setting temperature, and 20–25 Hz is the inverter panel speed. With 70–100 kilos of heat transfer sublimation paper and 80–180 grams of fabric, 35–50 meters of transfer can often be finished in an hour.

Technical paramters

Item | Data | |

Total Power | 11.2KW | |

Drum diameter | 215mm | |

Drum width | 1800mm (other drum widths are available) | |

Temperature range | 0-260℃ | |

Pressure range | 0-8kg | |

Control panel | Digital button control | |

Main motor power | 0.4KW | |

Heat transfer power | 7.8KW | |

Automatic shutdown | Yes | |

Automatic blanket alignment | Yes | |

Adjustable blanket length | Yes | |

Safety design | Yes | |

Heating type | Thermal oil heating | |

Voltage | 220V 1 phase/220V 3 phase/380V 3 phase | |

Number of air shaft | 2 | |

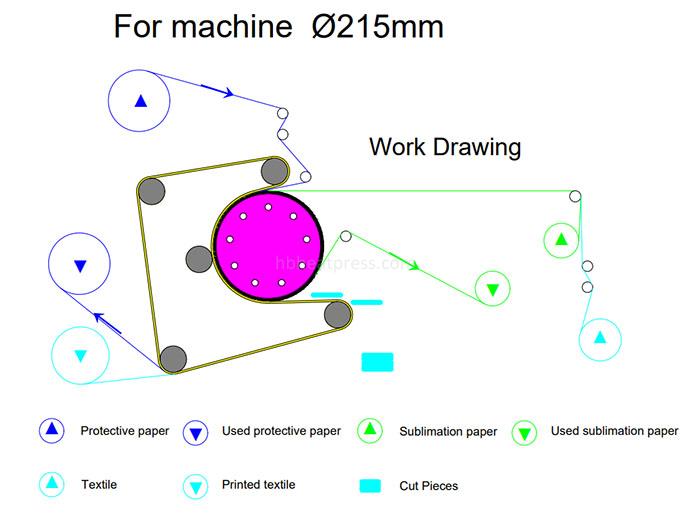

Working way | Roll to roll, roll to pieces, pieces to pieces | |

Packing dimension | 245x95x156cm |

Working flow

Quality control for roll heat press

How to choose a suitable calander sublimation

How to maintain the roll heat press

Contact: Yina Liu

Phone: +8613424008477

Tel: +8613424008477

Email: info@hbheatpress.com

Add: No.1, Lane 1, Liuyang street, Baisha, Zhongluotan, Baiyun district, Guangzhou, China

We chat