Woking table length: 2m Drum width: 1.8M Drum diameter: 210mm Voltage: 220V 1 phase, 220V 3 phase and 380V 3 phase Functions: Automatic shutdown, automatic pneumatic pressure, etc.

Features

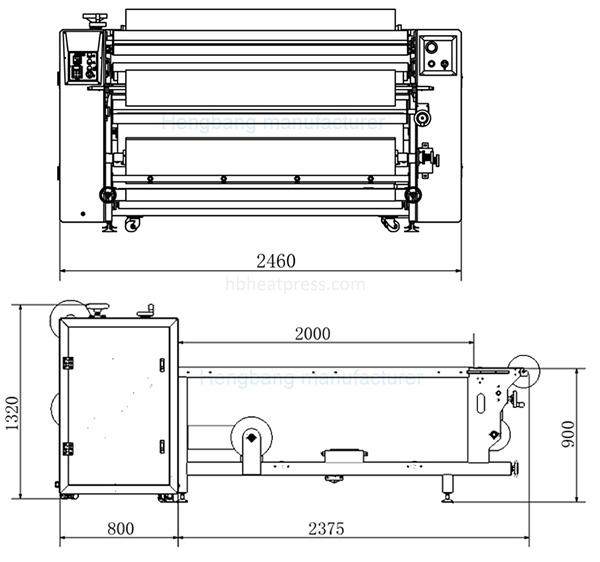

This calandra 1.8m has a choice between a workbench that is 80 cm long or 2 meters long. You can select an 80 cm long workbench for shops that lack adequate space. A 2-meter workbench is an option for individuals who have the room and require 2 meters for operation.

Whatever small sliced parts or the complete roll of fabric, the oil heats uniformly over the entire drum, giving you an evenly distributed printing outcome.

The shaft for used sublimation paper uses an air-expanding roller, which has the benefit of being simpler to operate than a regular shaft. Inflate the air shaft after first inserting the paper tube sleeve into it. It will stop the paper tube from moving after air shaft expands for 3-5 seconds.

After the sublimation paper is used, wind the sublimation paper onto the air expansion shaft. When a relatively large volume is collected, you can take out the infltable shaft, and then press the button on the air expansion shaft to release the air in the air expansion shaft. At this time, the waste paper can be easily taken out.

The sublimation textile calander is more common than the large flatbed heat press. Because it has a voltage that can be single-phase and more energy efficient than flatbed transfer machines.

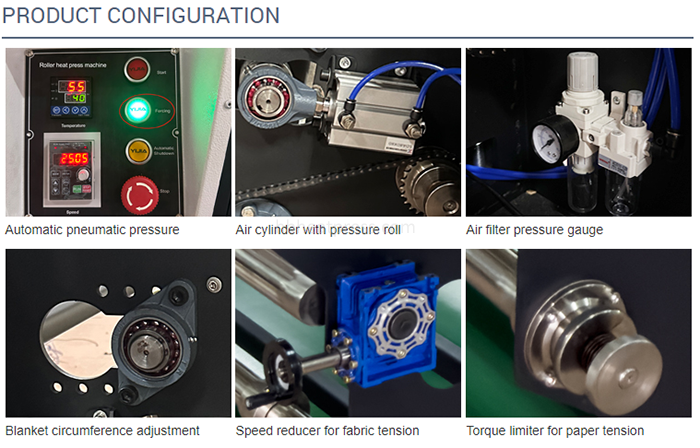

Depending on the sublimating substrates thickness, customers can choose whether to activate the machine's pressurization feature.

Unique system of rectification. Consists of a motor, spring, belt, and photoelectric switch. The photoelectric switch will detect this signal when the blanket is deflected to the point of pushing the spring. This will activate the motor and cause the deflection roller to move up and down.

Technical parameters

Item | Data |

Drum type | Chrome-plated |

Drum diameter | 215mm |

Drum width | 1800mm (other drum widths are available) |

Temperature range | 0-260℃ |

Control | Button control |

Total power | 11KW |

Main motor power | 0.4KW |

Heat transfer power | 7.7KW |

Automatic shutdown | Yes |

Automatic blanket alignment | Yes |

Adjustable blanket length | Yes |

Automatic pneumatic pressure | Yes |

Heating type | Thermal oil heating |

Voltage | 220V 1 phase/220V 3 phase/380V 3 phase |

Number of air shaft | 1 |

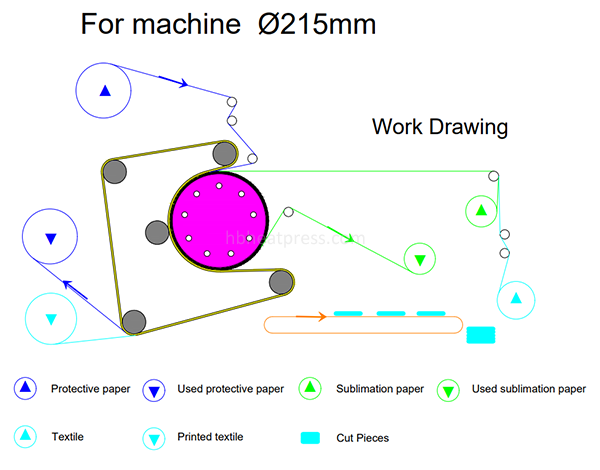

Working way | Roll to roll, roll to pieces, pieces to pieces |

Packing dimension | 255x101x158cm |

Working flow

Sublimation calandra dimension

Quality control for roll heat press

How to choose a suitable calander sublimation

How to maintain the roll heat press

Contact: Yina Liu

Phone: +8613424008477

Tel: +8613424008477

Email: info@hbheatpress.com

Add: No.1, Lane 1, Liuyang street, Baisha, Zhongluotan, Baiyun district, Guangzhou, China

We chat