Drum type: chrome-plated Heating type: Oil heating Suitable for: Roll to roll and roll to pieces sublimation fabric printing Temperature range: 0-260℃ Sublimation speed: Adjustable

Features

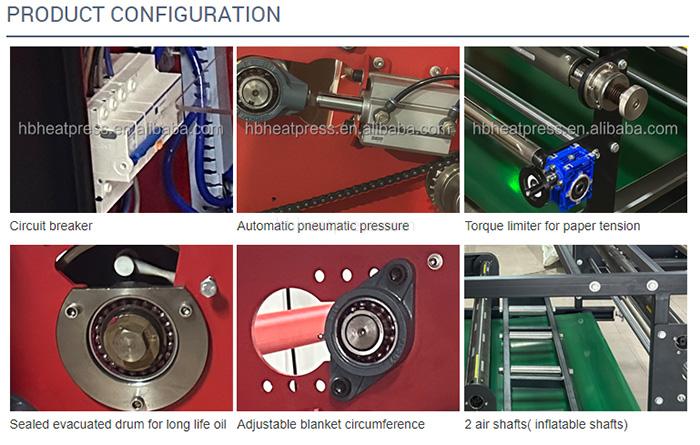

Because it incorporates PLC touch screen control, we named it the high-end version. And it makes use of premium materials. For example, the price of conductive metal rotor flange slip rings, which ensure temperature stability, is 25 times more than that of plastic slip rings. For the entire air shaft, aluminum is used. The drum surface is chrome-plated, the drum wall is thickened, etc.

It has automatic pneumatic pressure function and is ideal for all types of fabric sublimation heat transfer.

It comes with 2 air shafts. One is for used sublimation paper rewinding and the other one is for used protective paper rewinding.

The circuit breaker is not only for the safety of the operator, but also for helping check problem. If electricity leakage happens, it will automatically trip. If the thermal overload relay is broken, it will automatically trip, etc.

For such a small drum diameter calandra, it only have 2 motors, one is for automatic blanket alignment and the other one is main motor for controlling the entire machine, so the high quality main motor is important.

Sealed evacuated drum makes the thermal heat transfer oil service time much longer. It saves you the cost and time of replacing oil.

Printed fabric can be rewinding up by the roll at the back side of the calendar.

Technical parameters

Item | Data |

Drum type | Durable chrome-plated drum |

Drum diameter | 215mm |

Drum width | 180cm ( other drum widths are available) |

Temperature range | 0-260℃ |

Touchscreen control | Yes |

Language | English and Espanol |

Total power | 11KW |

Heat transfer power | 7.7KW |

Automatic shutdown | Yes |

Automatic blanket alignment | Yes |

Adjustable blanket length | Yes |

Safety design | Yes |

Heating type | Thermal oil heating |

Voltage | 220V 1 phase/220V 3 phase/380V 3 phase |

Number of air shaft | 2 |

Working way | Roll to roll, roll to pieces, pieces to pieces |

Packing dimension | 265x101x152cm |

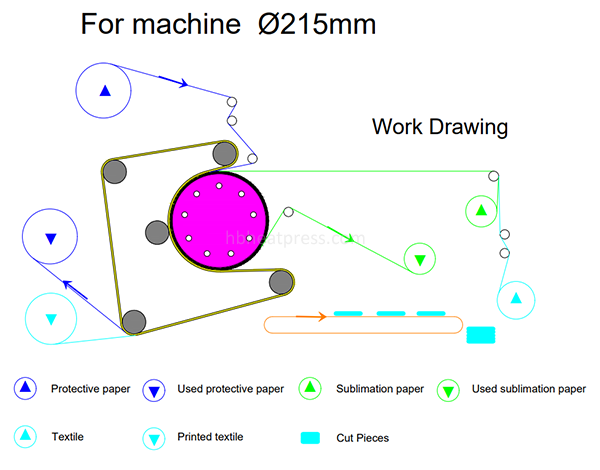

Working flow

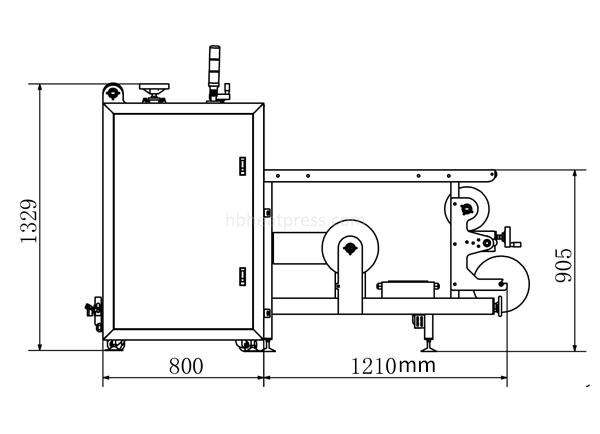

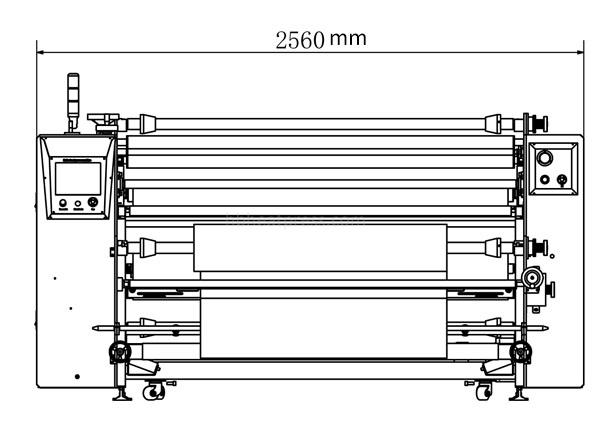

Sublimation calender dimension

Quality control for roll heat press

How to choose a suitable calander sublimation

How to maintain the roll heat press

Contact: Yina Liu

Phone: +8613424008477

Tel: +8613424008477

Email: info@hbheatpress.com

Add: No.1, Lane 1, Liuyang street, Baisha, Zhongluotan, Baiyun district, Guangzhou, China

We chat