Woking table length: 2m Drum width: 1700mm Drum diameter: 210mm Voltage: 220V 1 phase, 220V 3 phase and 380V 3 phase Functions: Automatic shutdown, automatic pneumatic pressure, etc. Heating type: Oil heating

Features

If the substrates are beach towel, fleece blanket, large gaming mouse pad, etc., this 210mm drum diameter calandra with a long table would be easier for operation. And the PVC conveyor belt with transport the printed products to the end of table, during the transportation process, the products cool down. A carton can be placed at the end of table for collecting the printed products.

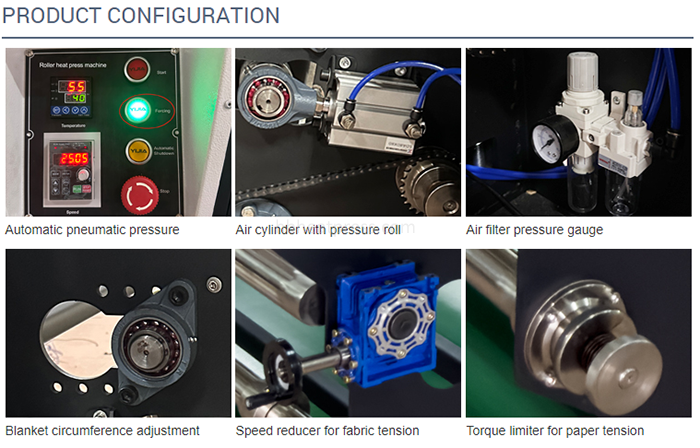

Forcing button is to control the air cylinder to move the pressure roll to contact the blanket for getting more pressure.

The air filter pressure gauge can be pulled up and turned to adjust pressure after air compressor is connected to the calandra. Thin fabric needs bigger pressure.

After running long time, the blanket circumference will become longer due to stretching. At the moment, the roll can be moved to the next position to get the blanket tighter.

Speed reducer is for the fabric tension and torque limiter is for the paper tension.

Digital button-control, simple easy to use. The drum speed is adjustable.

The left and right side have 2 small pallets for putting small tools.

Sublimation speed can be adjusted as per the temperature, substrate thickness, materials, etc.

Temperature range is 0-260℃ due to the fire point of thermal oil is 270℃.

Technical parameters

Item | Data |

Drum type | Chrome-plated |

Drum diameter | 215mm |

Drum width | 1700mm (other drum widths are available) |

Temperature range | 0-260℃ |

Control | Button control |

Total power | 10.6KW |

Main motor power | 0.4KW |

Heat transfer power | 7.4KW |

Automatic shutdown | Yes |

Automatic blanket alignment | Yes |

Adjustable blanket length | Yes |

Automatic pneumatic pressure | Yes |

Heating type | Thermal oil heating |

Voltage | 220V 1 phase/220V 3 phase/380V 3 phase |

Number of air shaft | 1 |

Working way | Roll to roll, roll to pieces, pieces to pieces |

Packing dimension | 245x101x158cm |

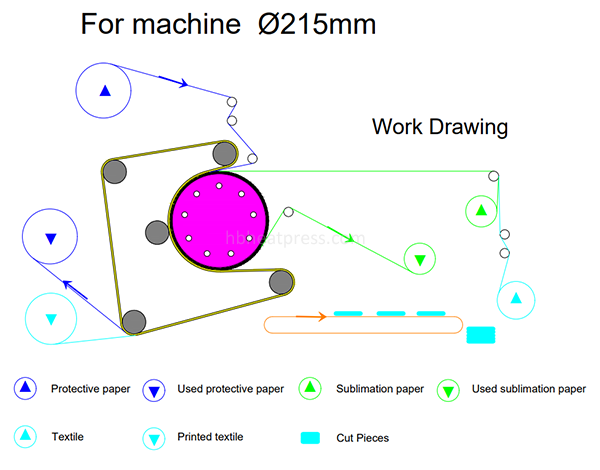

Working flow

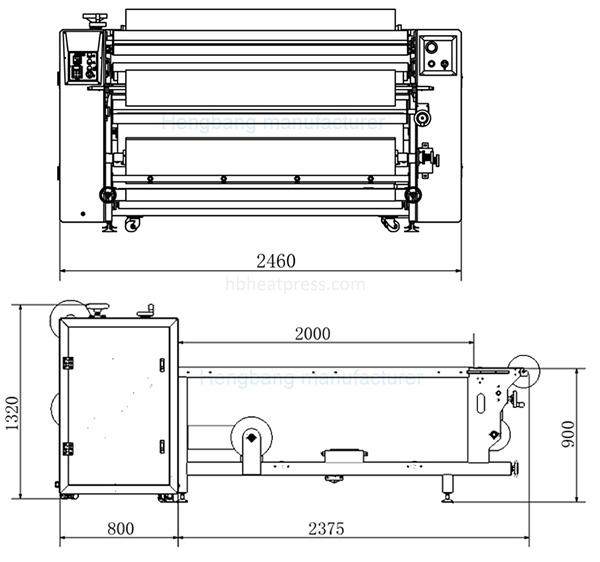

Sublimation calandra dimension

Quality control for roll heat press

How to choose a suitable calander sublimation

How to maintain the roll heat press

Contact: Yina Liu

Phone: +8613424008477

Tel: +8613424008477

Email: info@hbheatpress.com

Add: No.1, Lane 1, Liuyang street, Baisha, Zhongluotan, Baiyun district, Guangzhou, China

We chat