Ideal for: Roll to roll and roll pieces sublimation job Cylinder diameter: 32cm Cylinder width: 200cm Voltage: 380V 3 phase Temperature range: 0-260℃ Heating method: Oil heating

Features

We have created a new diameter of 320mm for clients to choose from because for certain customers, the 210mm diameter heat roller press is too slow but the 420mm diameter's power is too great. But rather than the 210mm type, it has the same design as the 420mm style.

The calandra can switch the drum forward and reverse at any time. In addition, pressing the emergency stop can make the blanket detach from the drum, or hit the pull-cord cable to make the blanket detach from the drum. Therefore, the operator can choose to reverse the drum or let the blanket detach from the drum according to needs.

You can see from the picture that the current is 25A-26A-27A, because it shows the real-time current according to the actual voltage during the heating up process.

Most customers will choose a calandra equipped with a fabric basket, because users can directly put the rolled fabric into the basket without threading the rod. Most customers have encountered the problem that the paper tube of fabric is deformed, making it difficult to thread the shaft through. Each roller in the textile basket is constructed from sturdy material and spray-painted to prevent rust or deformation over time.

Sublimation polyester temperature, drum speed, pressure, blanket pressure, etc., and air shaft speed can all be adjusted according to actual needs.

The light on the top of the machine can display three statuses of the machine: running, cooling, and alarm.

Tehcnical parameters

Item | Data |

Drum type | Durable chrome-plated double-layer |

Drum diameter | 320mm |

Drum width | 2.0 m (other drum widths are available) |

Temperature range | 0-260℃ |

Control | Button control |

Main motor power | 0.55KW |

Other motors power | 0.15KW and 0.18KW, etc. |

Preheating power for 380V 3 phase | 17KW |

Amperage for 380V 3 phase | 26A |

Preheating power for 220V 3 phase | 15KW |

Amperage for 220V 3 phase | 39A |

Automatic pneumatic pressure | Yes |

Automatic blanket alignment | Yes |

Adjustable blanket length | Yes |

Automatic blanket moving | Yes |

Take-up system for printed textile | Optional |

Fume exhaust system | Optional |

Textile basket | Optional |

Number of air shaft | 2 |

Working way | Roll to roll, roll to pieces, pieces to pieces |

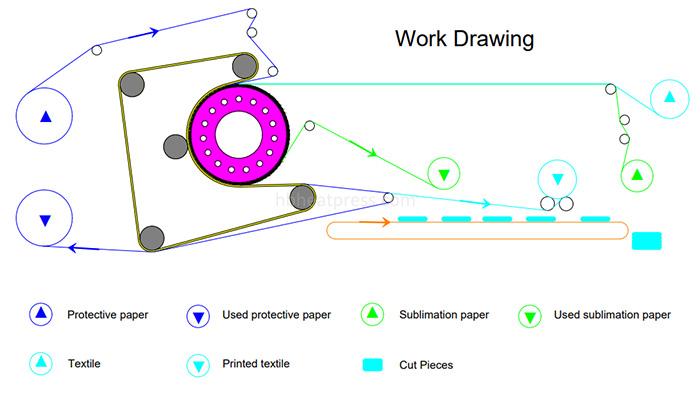

Working drawing

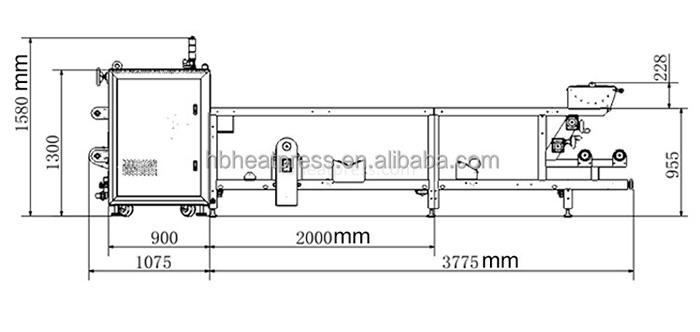

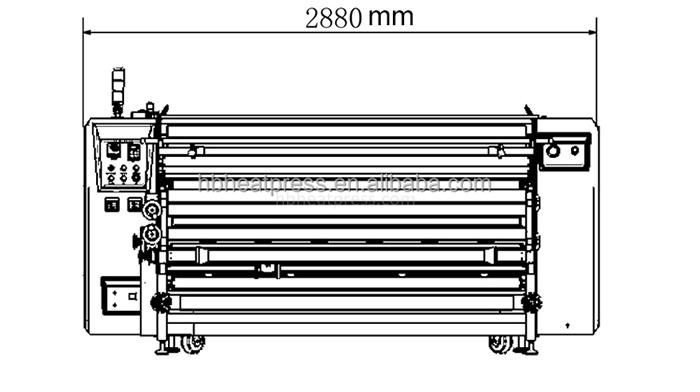

Calender sublimation dimension

FAQ:

Q1: Which drum width should I choose?

A1: If the printing width is 1,85 m, you can choose the 2.0 m drum width.

Q2: How many meters per hour it can transfer?

A2: Sublimation speed is 50 to 70 meters per hour.

Q3: Which type of drum do you use?

A3: We use the chrome-plated drum. It is more durable, anti-stretching, etc.

Q4: How do I know when I need to hit the pressure button?

A4: When you print low-gram fabric, you need to hit the pressure button.

Q5: How do I install the calandra when I receive it?

A5: We have the PDF for instructions of assembly.

Quality control for roll heat press

How to choose a suitable calander sublimation

How to maintain the roll heat press

Contact: Yina Liu

Phone: +8613424008477

Tel: +8613424008477

Email: info@hbheatpress.com

Add: No.1, Lane 1, Liuyang street, Baisha, Zhongluotan, Baiyun district, Guangzhou, China

We chat