Working method: Roll to roll fabric transfer sublimation printing Drum width: 1.8m (other sizes are available) Drum diameter: 800mm Voltage: 220V 3 phase, 380V 3 phase

Features

The polyester fabric with spandex roll-to-roll heat transfer printing works perfectly with this Calandra transfer thermal machine. Because the blanket covers a larger portion of the drum, it operates faster than a roll heat press machine with a table and with a same drum diameter.

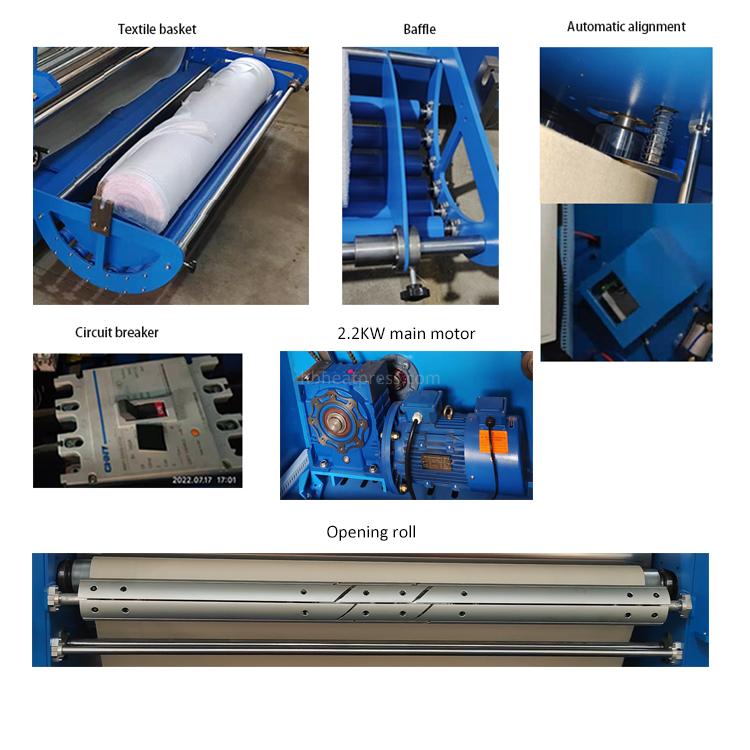

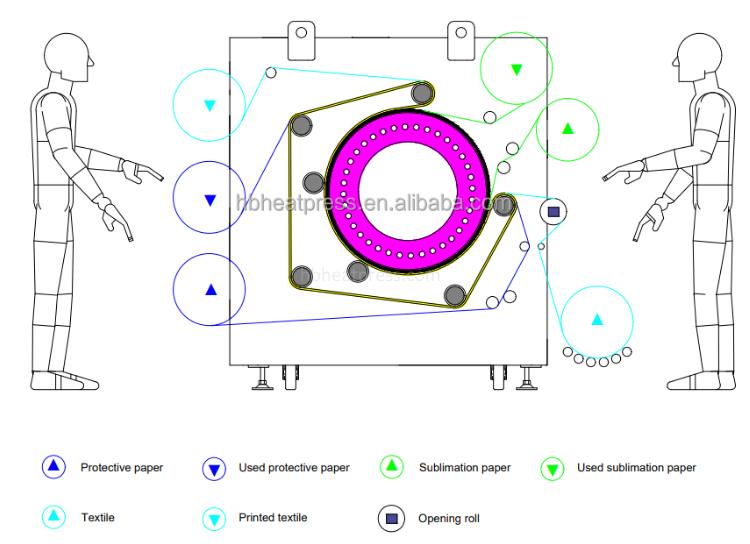

There are five inflatable air shafts in all. These are for loading sublimation paper, winding used sublimation paper, loading protecting paper, winding used protective paper, and winding printed fabric.

What is an air shaft?

An inflatable shaft is a shaft that can be expanded by inflating its air nozzle.So after loading the sublimation paper, inflating it will prevent it from moving.

When used up, just press the position of the air nozzle to deflate it, and it will return to its original shape, and the paper tube can be easily pulled out.

Whether it is fabric with or without a paper tube, we can place it directly in the fabric basket. Then push the left and right baffles against the fabric and secure them.

From lower to upper, it feeds. The top inflatable shaft at the back of the calendar takes up the printed fabric that emerges from the top. The fabric must go through the opening roller before it can enter the machine. The fabric can be unfurled to guarantee the transfer effect, and the goal is to keep it from being stretched and deformed.

The PLC touch screen adjusts the blanket tension to provide even, precise tension.

By pushing the blanket advance button, the blanket can be made to travel toward the operating panel until it is in position because it is controlled by a separate motor, reducer, and limit switches.

To travel in the other direction until it is totally detached from the drum, press the emergency stop button.

Of course, if there is a sudden power outage and the machine temperature exceeds 100 degrees, you need to ensure that you turn the black handwheel on the back of the machine within two minutes to separate the blanket from the drum.

Since the diameter of the drum is 80cm, we use a 2.2KW main motor with enough power to drive the drum.

We always put the safety of users first, so the leakage protection switch is particularly important. Regardless of whether the customer receives the machine and is connected to the circuit breaker with the right leakage protection function, we install the leakage protection directly on the machine.

This can prevent the machine from automatically tripping if there is leakage caused by aging electrical components in the future.

The calendar heat press is quite rapid, in contrast to the 210mm drum diameter, hence the automatic felt deflection adjustment function is required. The blanket can veer off course more easily at higher speeds. The automatic deviation correction system will promptly rectify it once it deviates.

Technical parameters

Item | Data |

Total Power | 53KW (220V 3 phase) |

Total power | 60KW (380V 3 phase) |

Drum width | 1800mm (other drum widths are available) |

Drum diameter | 800mm (420mm and 600mm are available) |

Speed | Adjustable |

Temperature range | 0-260℃ |

Touchscreen control | Yes (Ordinary control is available also) |

Language | English and Espanol |

Automatic shutdown | Yes |

Automatic blanket alignment | Yes |

Adjustable blanket length | Yes |

With textile basket | Yes |

With opening roll | Yes |

Heating type | Thermal oil heating |

Number of air shaft | 5 |

Working way | Roll to roll |

Blanket tension setting | Set by touch screen |

| Packing dimension | 295x200x200cm |

| Volume | 11.8CBM |

| Gross weight | 3570kg |

Working flow

Calendar heat press package

Quality control for roll heat press

How to choose a suitable calander sublimation

How to maintain the roll heat press

Contact: Yina Liu

Phone: +8613424008477

Tel: +8613424008477

Email: info@hbheatpress.com

Add: No.1, Lane 1, Liuyang street, Baisha, Zhongluotan, Baiyun district, Guangzhou, China

We chat