Working way: cut pieces to cut pieces sublimation printing Heating method: Oil heating Voltage: 220V 3 phase, 380V 3 phase Function: Automatic substrates feeding in, automatic blanket alignment, etc.

Features

Generally, most rotary heat presses do roll-to-roll and roll-to-sheet, but this calender sublimation printing machine is not, it is specially used for cut-to-cut. Since it is cutting piece to piece, it is obviously the simplest and most convenient mode to use top feeding and automatic feeding.

A sufficiently thick 14mm roller wall is the basis for ensuring that the roller does not deform. And a good roller is the core of a machine, affecting the transfer effect.

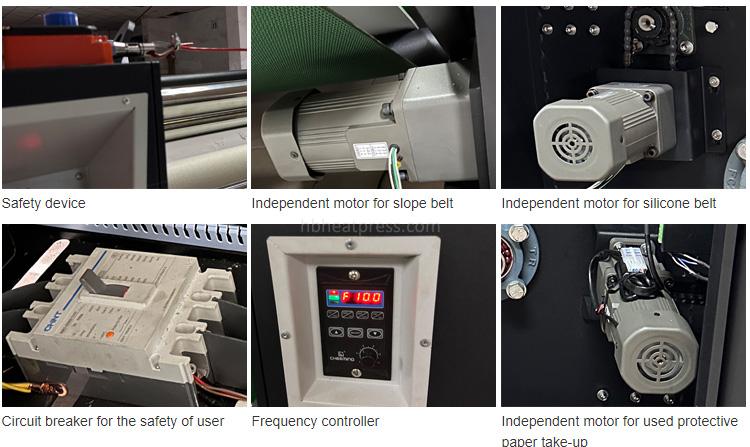

Not only the white silicone conveyor belt of the table is controlled by a frequency speed controller, but the slope conveyor belt is also controlled by a frequency speed controller. The cost is much higher than that of ordinary speed regulators, and it is also more stable and durable.

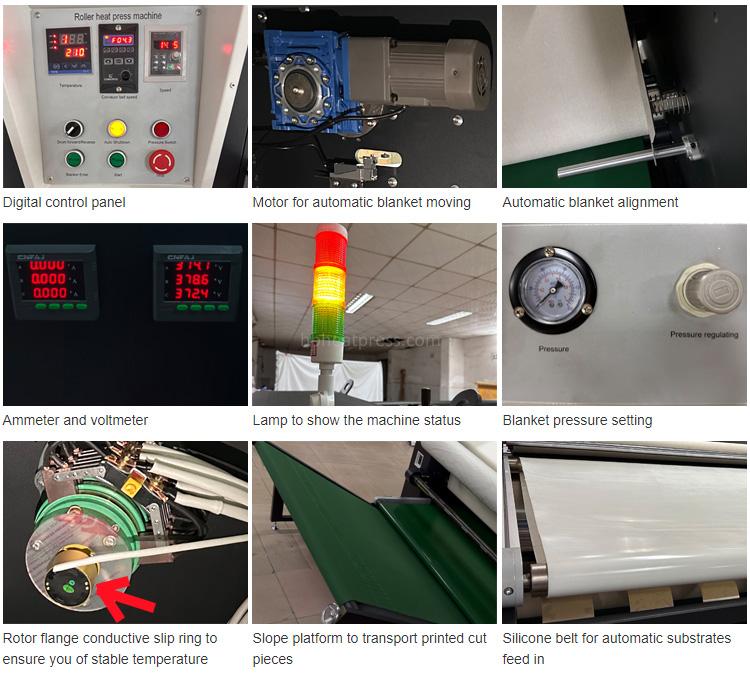

Drum speed and blanket tension are both adjustable.

The forward and reverse rotation of the drum can be switched at any time.

The automatic edge correction system using baffles and compression springs connected to the motor makes edge correction more accurate.

Technical parameters

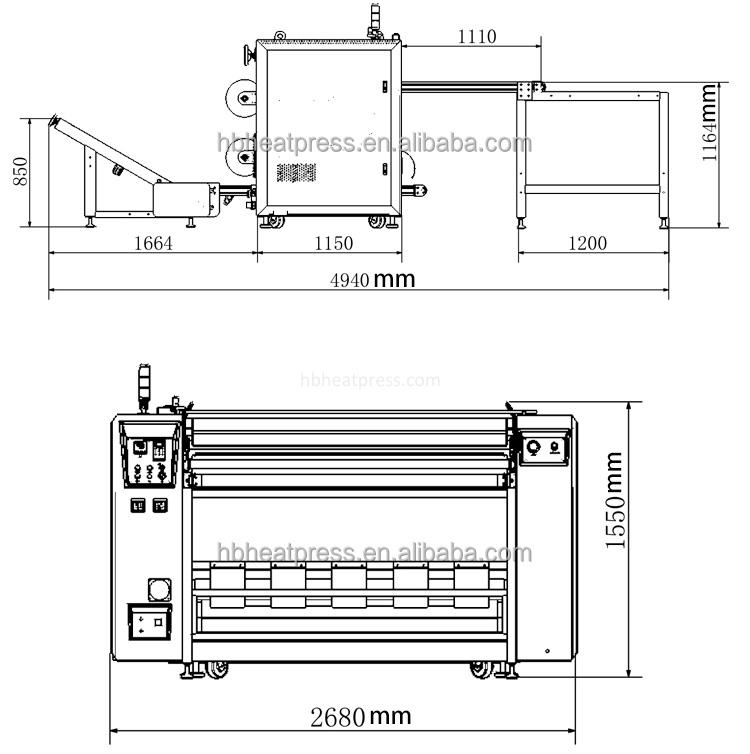

Calandra dimension

Rotary calander transfer package

Quality control for roll heat press

How to choose a suitable calander sublimation

How to maintain the roll heat press

Contact: Yina Liu

Phone: +8613424008477

Tel: +8613424008477

Email: info@hbheatpress.com

Add: No.1, Lane 1, Liuyang street, Baisha, Zhongluotan, Baiyun district, Guangzhou, China

We chat