Ideal for: Roll to roll and roll pieces sublimation job Cylinder diameter: 32cm Cylinder width: 200cm Voltage: 380V 3 phase Temperature range: 0-260℃ Heating method: Oil heating

Features

Normally this calandra is used for sublimation sportswear, and some customers also use it to transfer press flags, game mats,yoga mats, floor mats, sheets, pillowcases, beach towels, etc. Different products and different substrates require adjusting temperature, speed and pressure to achieve perfect transfer results.

The calender’s versatility, intelligence, etc., lead to its higher price. For example, automatic blanket feeding and automatic separating systems composed of independent motors, reducers and limit switches, automatic blanket correction systems, fabric basket, etc.

The benefit of automated blanket feeding is that it will stop after feeding, saving you from having to spin the handwheel and determine whether it has been fed completely.

This reduces work and saves time.

Putting the fabric roll into the fabric basket saves you time in threading the fabric into the metal rod. When purchasing fabrics, you don’t need to worry about the fabric not having paper tubes. If you buy fabric with a paper tube, you don’t need to worry about the paper tube deforming and making it difficult to insert the shaft.

The operator can thread the other roll of sublimation paper through the shaft and put it on the machine before one roll of transfer paper is transferred, saving time.

The leakage protection switch aids in preventing potential future safety risks brought on by component leaks.

Tehcnical parameters

Item | Data |

Drum type | Durable chrome-plated double-layer |

Drum diameter | 320mm |

Drum width | 2.0 m (other drum widths are available) |

Temperature range | 0-260℃ |

Control | Button control |

Main motor power | 0.55KW |

Other motors power | 0.15KW and 0.18KW, etc. |

Preheating power for 380V 3 phase | 17KW |

Amperage for 380V 3 phase | 26A |

Preheating power for 220V 3 phase | 15KW |

Amperage for 220V 3 phase | 39A |

Automatic pneumatic pressure | Yes |

Automatic blanket alignment | Yes |

Adjustable blanket length | Yes |

Automatic blanket moving | Yes |

Take-up system for printed textile | Optional |

Fume exhaust system | Optional |

Textile basket | Optional |

Number of air shaft | 2 |

Working way | Roll to roll, roll to pieces, pieces to pieces |

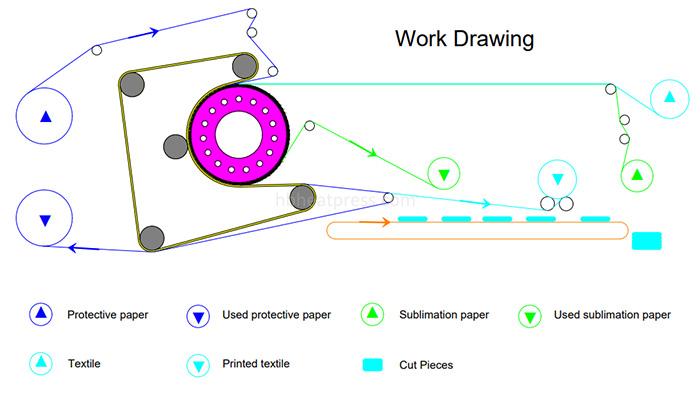

Working drawing

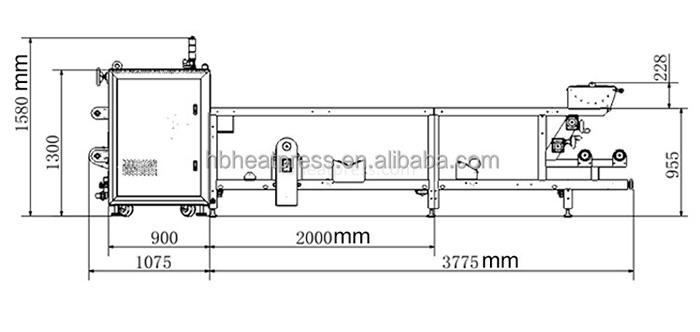

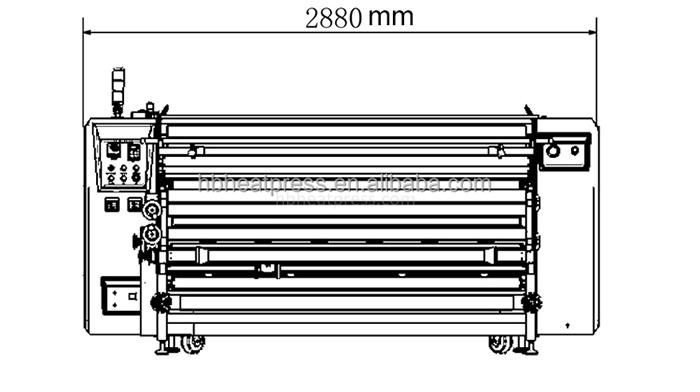

Calender sublimation dimension

FAQ:

Q1: Which drum width should I choose?

A1: If the printing width is 1,85 m, you can choose the 2.0 m drum width.

Q2: How many meters per hour it can transfer?

A2: Sublimation speed is 50 to 70 meters per hour.

Q3: Which type of drum do you use?

A3: We use the chrome-plated drum. It is more durable, anti-stretching, etc.

Q4: What is air shaft?

A4: Air shaft means it will be inflatable after you charge air for it. Use the air expansion to secure down paper tube instead of screws.

Q5: How do I install the calandra when I receive it?

A5: We have the PDF for instructions of assembly.

Quality control for roll heat press

How to choose a suitable calander sublimation

How to maintain the roll heat press

Contact: Yina Liu

Phone: +8613424008477

Tel: +8613424008477

Email: info@hbheatpress.com

Add: No.1, Lane 1, Liuyang street, Baisha, Zhongluotan, Baiyun district, Guangzhou, China

We chat