Roller width: 600mm Roller diameter: 210mm Roller type: Chrome-plated Voltage: 220V 1 phase, 220V 3 phase and 380V 3 phase Package type: Plywood case

Features

If your factory specializes in producing sublimated ribbons and the quantity is large, it is recommended to choose a 420mm or 600mm diameter calender. If the quantity is not very large, you can choose 210mm diameter. The flat double heating heat press for lanyard is about 5KW, but speed is very slow. This roll ribbon heat press is 6KW, but speed is much faster. So it definitely saves you time and cost.

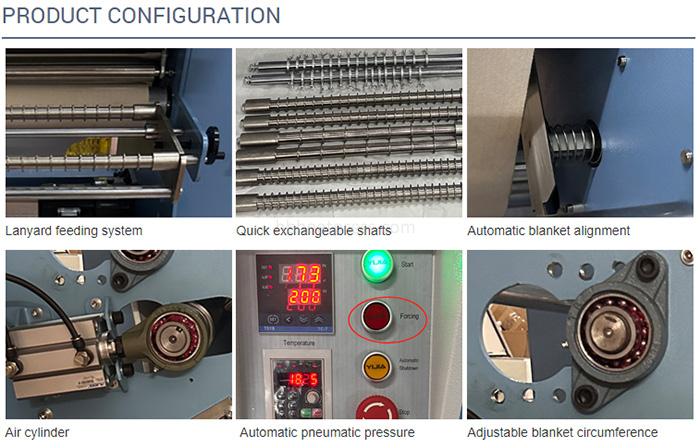

It can not only transfer double sides, but also transfer different sizes. From the position of the feed opening, you can see that there are two axes with interchangeable sizes. Therefore, if you transfer the 15 mm wide ones today and you want to transfer the 20 mm wide ones tomorrow, then you only need to change these two axes to 20 mm. That’s it.

When using a faster printing speed, the blanket may deviate. At this time, the automatic deviation correction system will automatically center it.

There are multiple hand wheels on the machine, One of them is used to enter and separate the blanket, the smallest one is used to adjust the left and right movement of the lanyards, and the top 2 are used to adjust the tightness of the ribbons.

The one-button pressure function on the machine can achieve better transfer results. Some thinner ribbons must have the pressurization function turned on.

The quiet and noiseless 0.4KW main motor ensures smooth operation of the whole machine.

Technical parameters

Item | Data |

Drum type | Durable chrome-plated drum |

Drum diameter | 215mm |

Drum width | 600mm ( other drum widths are available) |

Temperature range | 0-260℃ |

Touchscreen control | Yes |

Voltage | 220V 1 phase/220V 3 phase/380V 3 phase |

Total power | 6 KW |

Air compressor | Required |

Automatic shutdown | Yes |

Automatic blanket alignment | Yes |

Adjustable blanket length | Yes |

Safety design | Yes |

Heating type | Thermal oil heating |

Number of air shaft | 2 |

Double sided sublimation | Yes |

Working way | Roll paper to roll ribbon |

Packing dimension | 147x140x173cm |

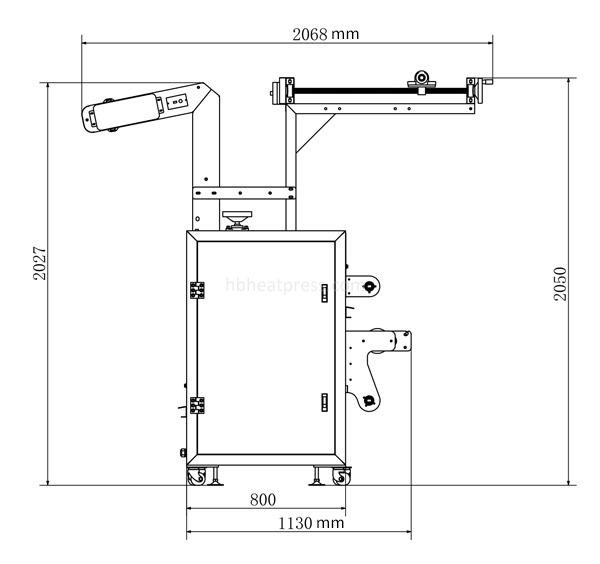

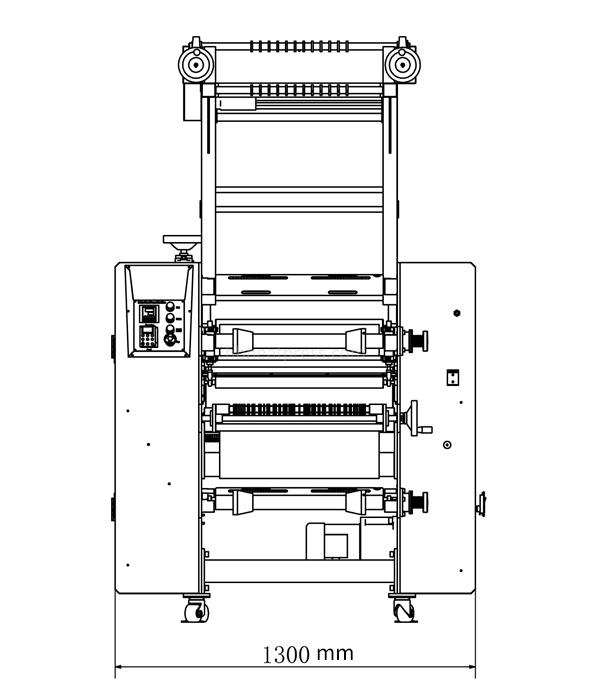

Ribbon calendar dimension

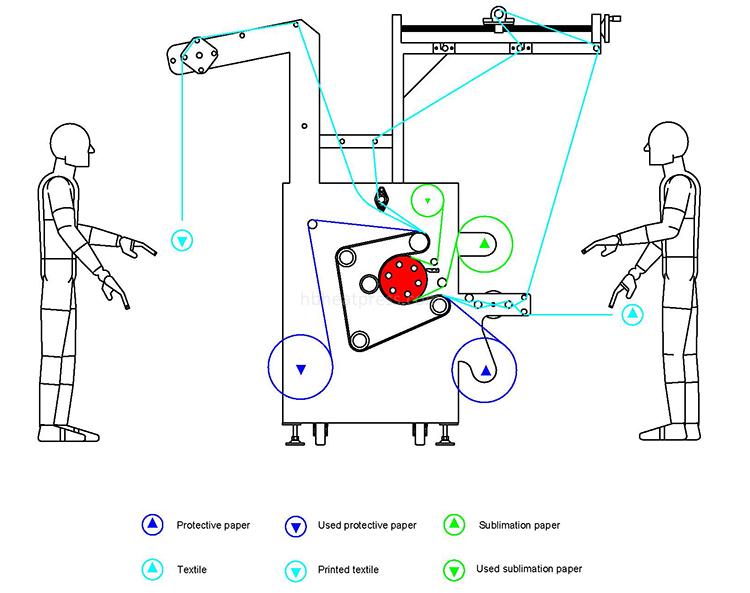

Working flow

FAQ:

Q1:Is it oil heated?

A1: Yes, it is thermal oil heated.

Q2: Do I need an air compressor for the calandra?

A2: Yes, you need it. It has pneumatic pressure function and the air shafts need to be charged air.

Q3: How many meters per hour it can transfer?

A3: Sublimation speed is 35 to 50 meters per hour for every single lanyard. But you can sublimate a few pieces at the same time.

Q4: Why do I need the automatic pneumatic pressure function?

A4: It is perfect for thin ribbon. And with the pneumatic pressure, you can sublimate with higher speed.

Q5: What is air shaft?

A5: Air shaft means it will be inflatable after you charge air for it. Use the air expansion to secure down paper tube instead of screws.

Q6: Can it be 220V 1 phase?

A6: Yes, it can.

Quality control for roll heat press

How to choose a suitable calander sublimation

How to maintain the roll heat press

Contact: Yina Liu

Phone: +8613424008477

Tel: +8613424008477

Email: info@hbheatpress.com

Add: No.1, Lane 1, Liuyang street, Baisha, Zhongluotan, Baiyun district, Guangzhou, China

We chat