Size: 16x20 inches and 16x24 inches Voltage: 220V 3 phase and 380V 3 phase Total power: 11KW Spray nozzle: 1 piece Spray nozzle height: adjustable Spray flow: adjustable Spray speed: adjustable

US$9000-US$10800

Features

An automatic DTG pretreatment machine is a device used in the textile industry to treat T-shirts or other garments with a special solution before printing. The purpose is to make the colors printed on clothes washable, non-fading, and more vivid and beautiful.

User-friendly interface: It has the control panel and touch screen where you can adjust settings such as spray flow, turntable speed, heat press temperature, pressing time, drying time, spray start position, spray end position, etc.

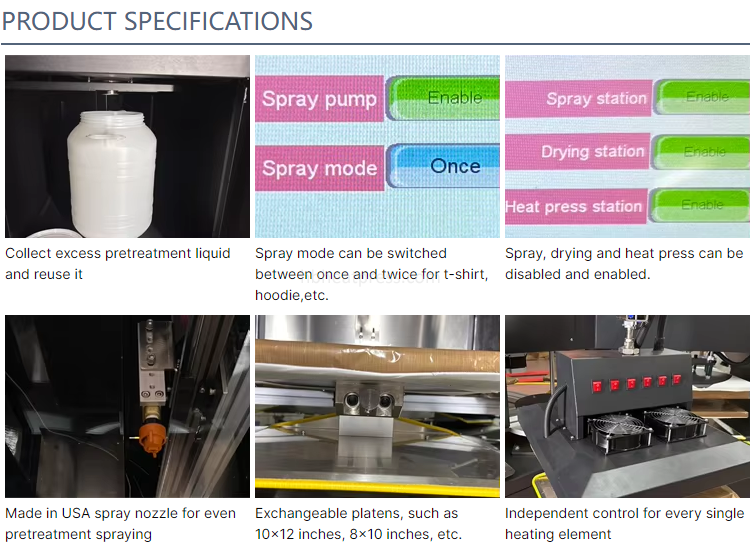

Adjustable spray nozzle height and speed: the height of the spray nozzle can be adjusted for various spraying area. Spray nozzle speed can be adjusted for spray flow changing.

Easy pretreatment: Since it is a rotary type machine, the work efficiency is greatly improved. Therefore, a large bucket of treatment liquid can be placed directly on the ground, and the pretreatment liquid is pumped up through a pump and a tube with a filter and sprayed directly onto the clothes. No need to go through the tedious process of putting it into vials.

Combine 3 machines into 1: The machine includes a drying system and a heat press to remove excess moisture from the garment before printing, then flat the garment by heat press to make sure the good printing result.

Compatible with various types of garments: Including T-shirts, hoodies, and sweatshirts, allowing for versatile usage in the garment printing industry.

Because the spray flow flow ranges from 0-100 and there are spraying mode once and twice. If twice mode, it means it can spray bi-direction.

Option for coming with exchangeable platens: such as 8x10 inches, 10x12 inches, 14x16 inches, etc.

Save pretreatment liquid: The excess treatment fluid will flow to the bottom plate of the spray station and then flow into the bucket to be collected.

Low maintenance: Built with rust-free materials included aluminum and stainless steel. All the areas that pretreat liquid can contact use stainless steel material. Heating platen and lower platen for heat press use aluminum material.

Ventilation: Built-in ventilation fans for the flash dryer help prevent mist from accumulating, ensuring a clearer operating environment and protecting machine components. And a fume exhaust system for the heat press ensures a clearer operating enviroment as well.

Parameters

Item | Data |

Voltage | 220V 3 phase and 380V 3 phase |

Total Power | 11KW |

Heat press power | 3.5KW |

Flash dryer power | 6KW |

Touch screen control | Yes |

Counting pieces display | Yes |

Drying time and pressing time | Both adjustable |

Drying temp. and pressing temp. | Both are adjustable |

Platen size | 40x50cm(16"x20") and 40x60cm(16"x24") |

Turntable speed | Adjustable |

Spray flow | Adjustable |

Distance between dryer and lower plate | Adjustable |

Net weight | 470kg |

Gross weight | 575kg |

Packing dimension | 222X130X170CM |

Package type | Plywood case |

HS Code | 8443399000 |

Quality control for roll heat press

How to choose a suitable calander sublimation

How to maintain the roll heat press

Contact: Yina Liu

Phone: +8613424008477

Tel: +8613424008477

Email: info@hbheatpress.com

Add: No.1, Lane 1, Liuyang street, Baisha, Zhongluotan, Baiyun district, Guangzhou, China

We chat