Working way: cut pieces to cut pieces sublimation printing Heating method: Oil heating Voltage: 220V 3 phase, 380V 3 phase Function: Automatic substrates feeding in, automatic blanket alignment, etc.

Features

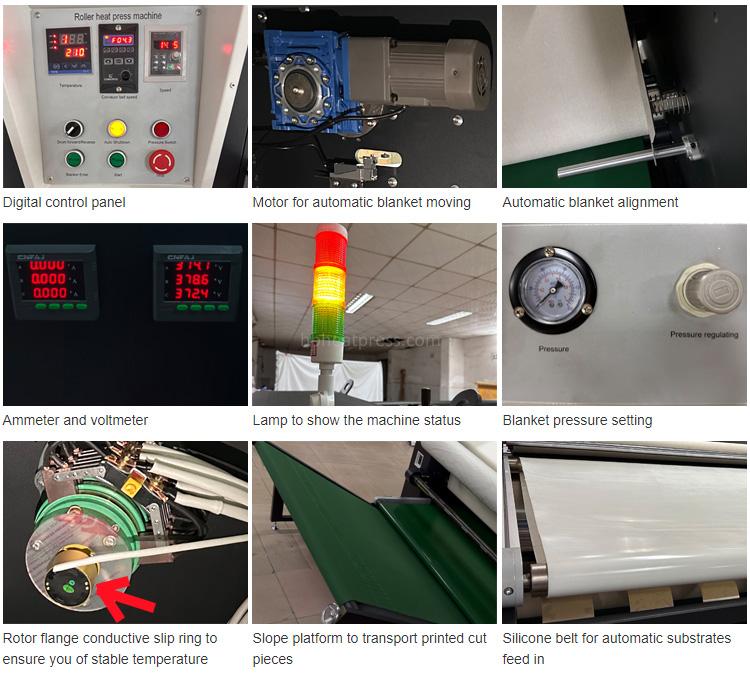

This rotary heat transfer machine is mainly used for cutting piece to piece sublimation. Therefore, there is no shafts for loading paper or loading fabric in front of it. The workbench is equipped with a high-temperature resistant silicone conveyor belt that can automatically feed materials.

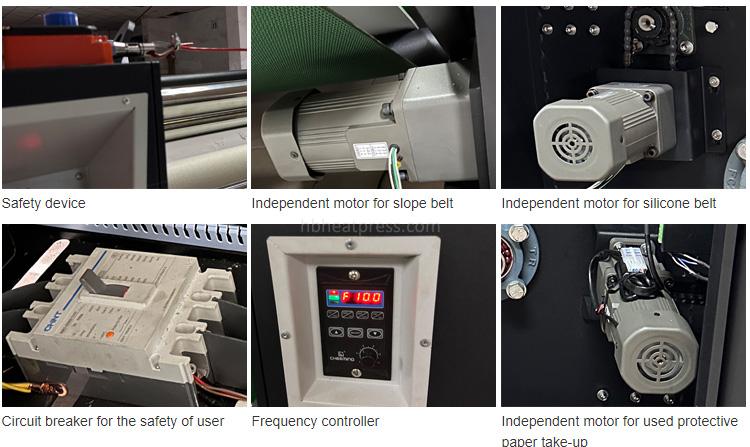

Since the white silicone conveyor belt has independent motor control, the left panel is equipped with a frequency converter, which can control the switch of the silicone conveyor belt and adjust the speed of the silicone conveyor belt.

Compared with ordinary green PVC conveyor belt, silicone conveyor belt is more resistant to high temperatures, durable and cost-effective.

High-priced conveyor belt materials must be utilized since they are in close contact with the oil roller and are subjected to high temperatures for an extended period of time.

The slope uses a conveyor belt with increased friction to prevent the pieces from slipping. There is a separate motor and frequency converter to control its switching and speed.

The 3-color lamp can show you the status of the calandra. In the picture , it was yellow color, so it means the "automatic shutdown" button was pressed.

Cost of the rotor flange conductive slip ring is much higher than the plastic mini slip ring. It can ensure you of stable temperature.

Technical parameters

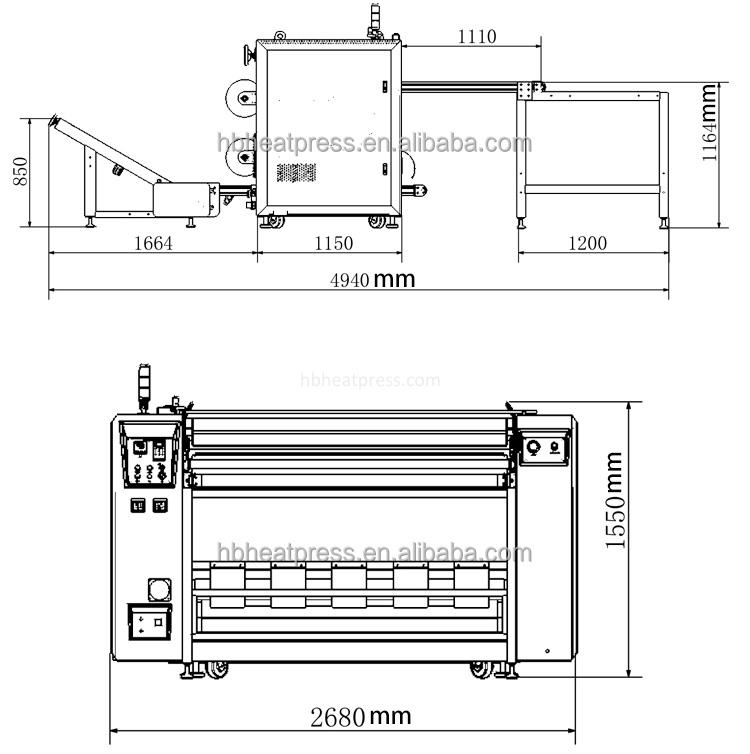

Calandra dimension

Rotary calander transfer package

Quality control for roll heat press

How to choose a suitable calander sublimation

How to maintain the roll heat press

Contact: Yina Liu

Phone: +8613424008477

Tel: +8613424008477

Email: info@hbheatpress.com

Add: No.1, Lane 1, Liuyang street, Baisha, Zhongluotan, Baiyun district, Guangzhou, China

We chat