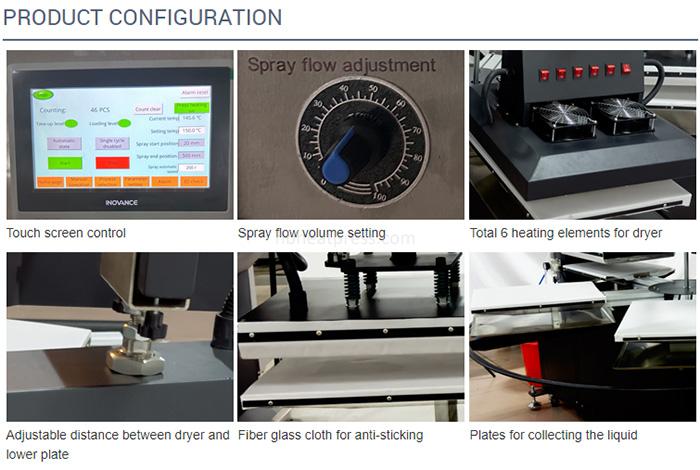

Size: 16x20 inches and 16x24 inches Voltage: 220V 3 phase and 380V 3 phase Total power: 11KW Control panel: Touch screen Spray flow: adjustable

Features

Many customers, we believe, are still employing separate pretreatment machines, dryers or heat presses.

Because they are unaware that we have developed a rotary machine that integrates pre-treatment, drying, and heat pressing into a single unit.

It is divided into five stations: loading, spraying, drying, heat pressing, and unloading.

It may alter the spray flow volume depending on whether the clothing are dark or light. It may change the spray range based on the situation.

It has the potential to significantly enhance job efficiency and reduce labor.

We can utilize one nozzle to ensure uniform spraying by configuring the program and selecting accessories, which saves treatment fluid and hence expenses.

If the garments are light in color, shorten the drying time or use a heat press.

If the garments are dark in color, you can increase the drying and heat pressing times.

The dryer has a total of 6 heating tubes, each 1KW, controlled by 6 independent buttons. You can choose to turn on any one, several or all of them according to your needs.

The space between the dryer and the bottom plate can be adjusted.

The stainless steel cover protects the silicone pad from shifting during rotation.

To ensure that garments may be readily placed on the base plate, each base plate is wrapped in Teflon high-temperature glass-fiber cloth.

There is an extra plate under each bottom plate to ensure that if treatment fluid is sprayed, it will drip onto the plate rather than polluting the ground.

The heat press's heating plate is additionally wrapped in a high-temperature fabric to guarantee that the treatment liquid does not adhere to the heating plate and that it is easy to clean.

Technical parameters

Item | Data |

Voltage | 220V 3 phase and 380V 3 phase |

Total Power | 11KW |

Heat press power | 3.5KW |

Flash dryer power | 6KW |

Touch screen control | Yes |

Counting pieces display | Yes |

Drying time and pressing time | Both adjustable |

Drying temp. and pressing temp. | Both are adjustable |

Platen size | 40x50cm(16"x20") and 40x60cm(16"x24") |

Turntable speed | Adjustable |

Spray flow | Adjustable |

Distance between dryer and lower plate | Adjustable |

Net weight | 470kg |

Gross weight | 575kg |

Packing dimension | 222X130X170CM |

Package type | Plywood case |

HS Code | 8443399000 |

FAQ:

Q1: Is the spray flow volume adjustable?

A1: Yes, it is.

Q2: Which air compressor do I need for it?

A2: You need the 1.1 KW power and 50L capacity air compressor.

Q3: Do I need to install the machine when I receive it?

A3: Yes, you need to install the turntable.

Q4: How many spray nozzle does it have?

A4: It has 1 spray nozzle.

Q5: How many units of this DTG pretreatment heat press machine can be loaded into a 20 ft container?

A5: 4 units.

Q6: If I need the exchangeable platens for kid's shirt, can you make it?

A7: Yes, we can.

Quality control for roll heat press

How to choose a suitable calander sublimation

How to maintain the roll heat press

Contact: Yina Liu

Phone: +8613424008477

Tel: +8613424008477

Email: info@hbheatpress.com

Add: No.1, Lane 1, Liuyang street, Baisha, Zhongluotan, Baiyun district, Guangzhou, China

We chat