Working way: Roll to pieces and cut pieces to cut pieces sublimation printing Heating method: Oil heating Voltage: 220V 3 phase, 380V 3 phase Function: Automatic substrates feeding in, automatic blanket alignment, etc.

Features

This calandra sublimation looks very similar to the other one. The other one is solely used for cutting pieces to cutting pieces because there is no shaft for loading sublimation paper in the table. This calandra table, however, includes two air shafts: one for loading sublimation paper and the other for gathering spent sublimation paper.

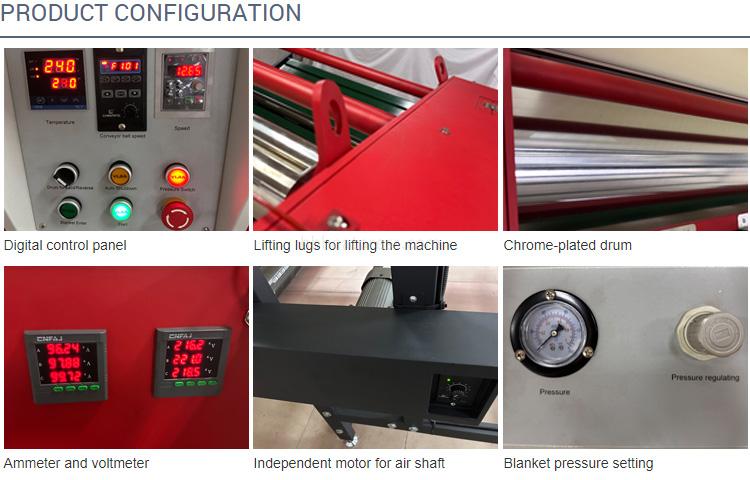

From the control panel, you can see there is a temperature controller, a speed controller for silicone belt, a speed panel for drum speed, switch for drum forwarder and reverse, automatic shutdown, pressure button, blanket enter button ,start button and stop button. You can choose whether to turn on the silicone conveyor belt and pressure switch according to your needs.

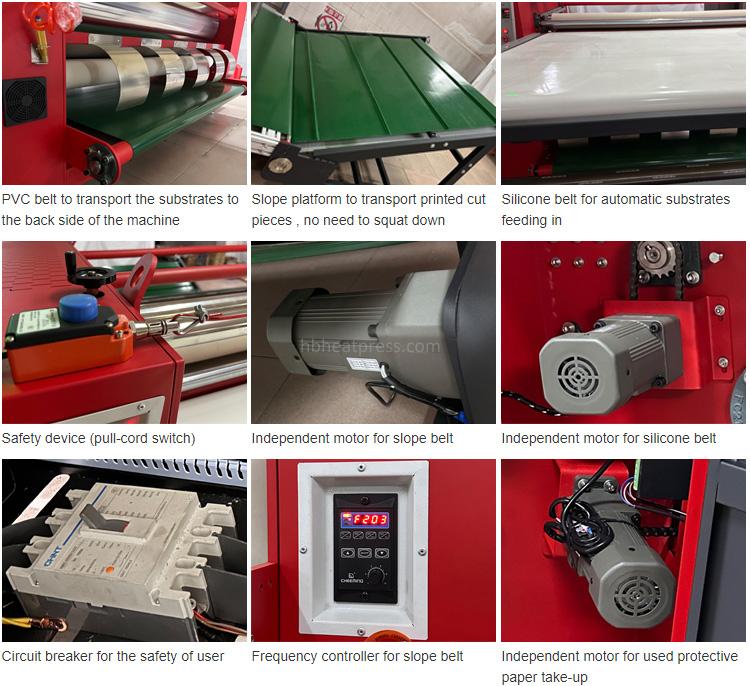

The blanket will automatically separate from the drum if the stop button is pressed or the pull-cord cable is pulled.

The material of the slope conveyor belt can be customized according to the size of the cut pieces or the type of cut pieces.

Due to its proximity to the roller and high temperature, the feed port employs silicone conveyor belt rather than PVC conveyor belt. The silicone conveyor belt can operate for an extended period of time in an environment with high temperatures without deforming.

To make sure that the transfer result is more vibrant and bright, it uses a chrome-plated drum. Without a doubt, a chrome-plated drum is more expensive than a coated drum, but it is also more durable.

Technical parameters

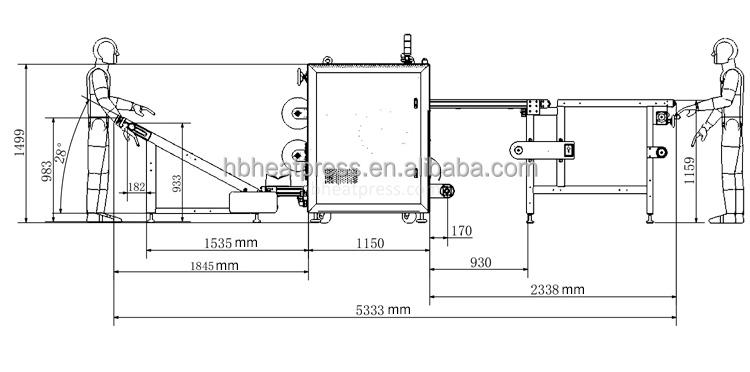

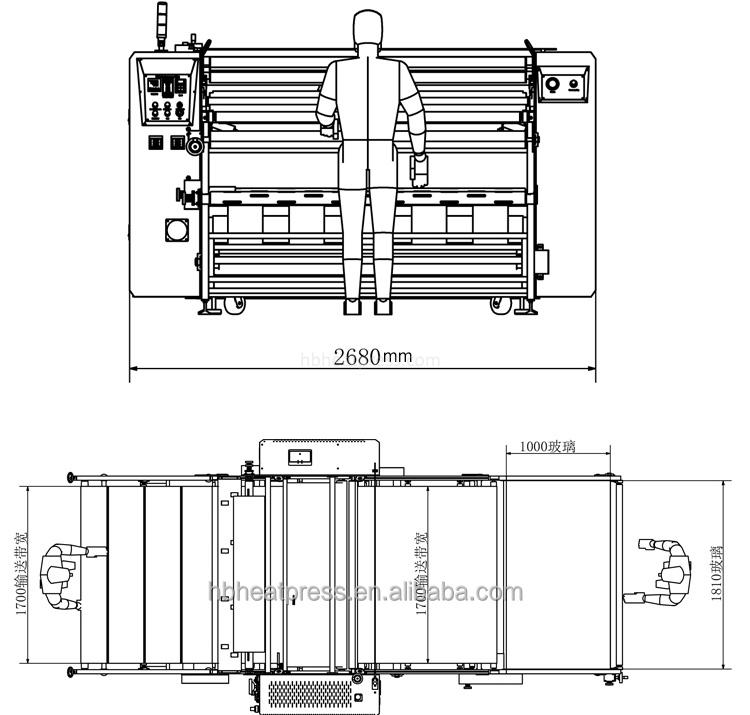

Calandra dimension

Quality control for roll heat press

How to choose a suitable calander sublimation

How to maintain the roll heat press

Contact: Yina Liu

Phone: +8613424008477

Tel: +8613424008477

Email: info@hbheatpress.com

Add: No.1, Lane 1, Liuyang street, Baisha, Zhongluotan, Baiyun district, Guangzhou, China

We chat