Working way: Roll to pieces and cut pieces to cut pieces sublimation printing Heating method: Oil heating Voltage: 220V 3 phase, 380V 3 phase Function: Automatic substrates feeding in, automatic blanket alignment, etc.

Features

As you can see from the table, this hot roll press machine does not have a textile basket or a metal rod for loading fabric rolls. Roll to roll sublimation heat transfer is not intended for it. It is designed for roll paper to cut pieces of substrates.

Here, the oil was purified and the blanket was cured before export. Upon receiving the calandra heat press, the table just needs to be put together, and once the electrical wiring is connected, it can be turned on to preheat and operate.

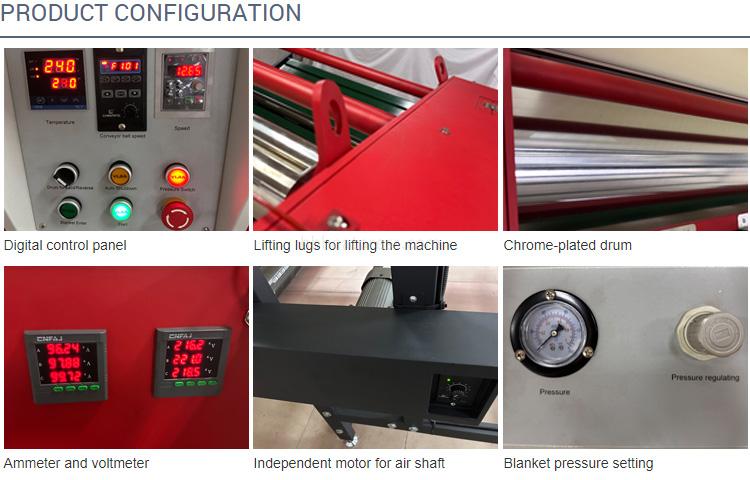

When sublimation printing, the drum forward/reverse switch ought to remain in the forward position.

Using a sufficiently thick drum is crucial for a heat transfer machine with a drum diameter of 42 cm (16"). It serves the dual purpose of preventing creases of sublimation result in addition to ensuring that it won't deform.

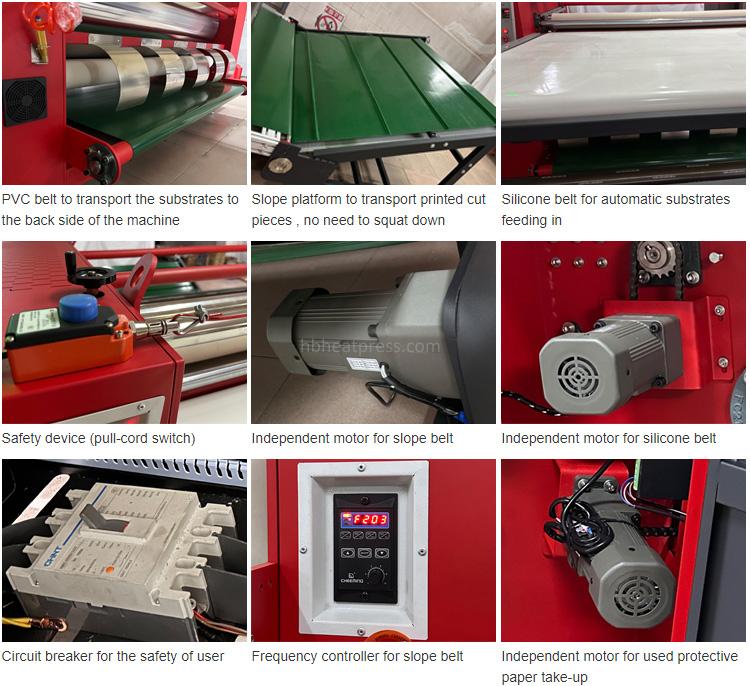

The top table belt is in close to the drum, so it is imperative to use a material that can withstand high temperatures. For this reason, we use silicone belts instead of PVC ones.

The chrome-plated drum is for providing you a more brightful sublimation result ensuring you of longer service time than teflon coated drum.

Technical parameters

Item | Data |

Drum type | Durable chrome-plated double-layer |

Drum diameter | 420mm (Other drum diameters are available) |

Drum width | 1.8 m (other drum widths are available) |

Temperature range | 0-260℃ |

Control | Button control |

Main motor power | 0.75 KW |

Other motors power | 0.25KW and 0.15KW, etc. |

Preheating power for 380V 3 phase | 25KW |

Amperage for 380V 3 phase | 38A |

Preheating power for 220V 3 phase | 22KW |

Amperage for 220V 3 phase | 58A |

Automatic pneumatic pressure | Yes |

Automatic blanket alignment | Yes |

Adjustable blanket length | Yes |

Automatic blanket moving | Yes |

Independent motor for the slope | Yes |

Independent motor for the silicone belt | Yes |

Discharging method | Come out from the bottom and transport to the back side of the calandra |

Number of air shaft | 4 |

Working way | Pieces to pieces and roll to pieces |

Packing dimension | 296x176x165cm |

Volume | 8.596CBM |

Quality control for roll heat press

How to choose a suitable calander sublimation

How to maintain the roll heat press

Contact: Yina Liu

Phone: +8613424008477

Tel: +8613424008477

Email: info@hbheatpress.com

Add: No.1, Lane 1, Liuyang street, Baisha, Zhongluotan, Baiyun district, Guangzhou, China

We chat