Drum width: available in 1200mm to 2000mm Drum diameter: 210mm Voltage: 220V 1 phase, 220V 3 phase and 380V 3 phase Table length: optional Temperature range: 0-260℃ Sublimation speed: Adjustable Pressure: Adjustable

Features

Hengbang has always been committed to manufacturing high-quality calendar heat press machines that satisfy customers. It uses heavy-duty frames, heavy-duty rollers, shafts, and high-quality components to ensure the consistent running.

The 210mm diameter calendar helps customers achieve a leap in dye sublimation printing output from large flat heat presses. While reducing power consumption, it increases the transfer speed and can print not only cut pieces but also roll fabrics. Color fixation is able to work as well.

According to the needs of our customers, we design this calandra machine with a drum diameter of 210 mm into a model with a diameter of 420 mm. This means that it has the function of automatic blanket forward and backward, independent paper delivery motor, double roller shaft take-up system with meter counter, separate motor control take-up system and so on.

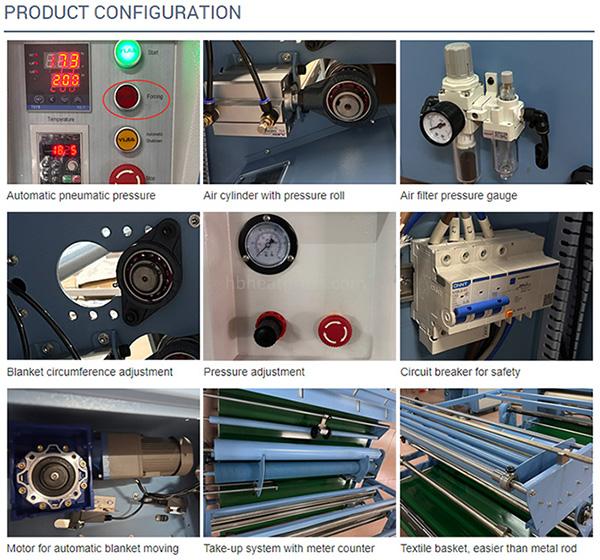

Even though it's 210 mm in diameter, we think the air press feature will always be important for some fabrics. So by pressing the pressurize button you can start cylinder pressurization.

There is no need to manually crank the hand wheel to feed the blanket, just press the button for feeding the blanket, and it will stop automatically after the blanket is in place

The double-drum shaft winding system controlled by an independent motor makes the transferred fabric wind up more smoothly.

The basket was originally designed for fabrics without a paper tube, because it has no paper tube to pass through the rod, but many customers have encountered the problem that the paper tube of the fabric is deformed, which makes it difficult for the fabric to pass through the metal shaft, which can be put it directly in the basket.

Simple and easy to adjust the circumference of the blanket. After the machine has been running for a year or more, the blanket will stretch and become loose. At this time, the blanket can be tightened by moving the blanket shaft to the next hole.

The pressure regulator on the right side of the machine can change the pressure of the blanket.

It has two rolls for sublimation paper so that one roll can be loaded first while the other roll is being transferred.

Technical parameters

Item | Data |

Drum type | Chrome-plated |

Drum diameter | 215mm |

Drum width | 1800mm (other drum widths are available) |

Temperature range | 0-260℃ |

Control | Button control |

Total power | 13KW |

Main motor power | 0.4KW |

Heat transfer power | 9KW |

Automatic shutdown | Yes |

Automatic blanket alignment | Yes |

Adjustable blanket length | Yes |

Automatic pneumatic pressure | Yes |

Heating type | Thermal oil heating |

Voltage | 220V 1 phase/220V 3 phase/380V 3 phase |

Number of air shaft | 2 |

Working way | Roll to roll, roll to pieces, pieces to pieces |

Packing dimension | 281x135x156cm |

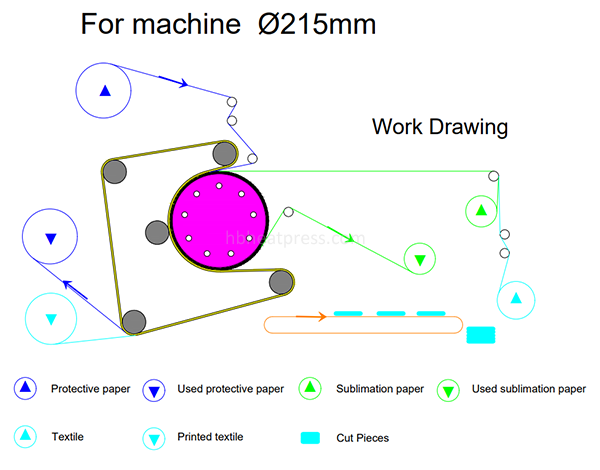

Working flow

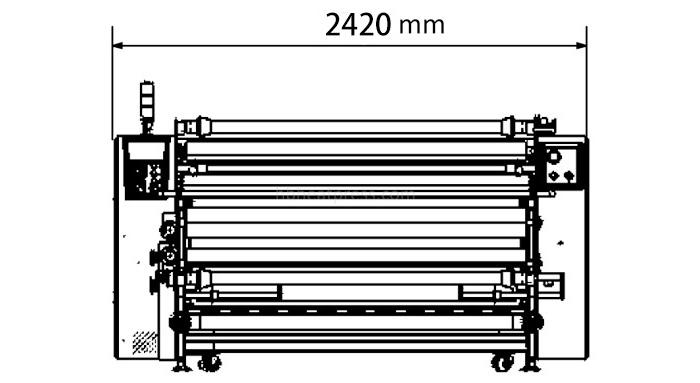

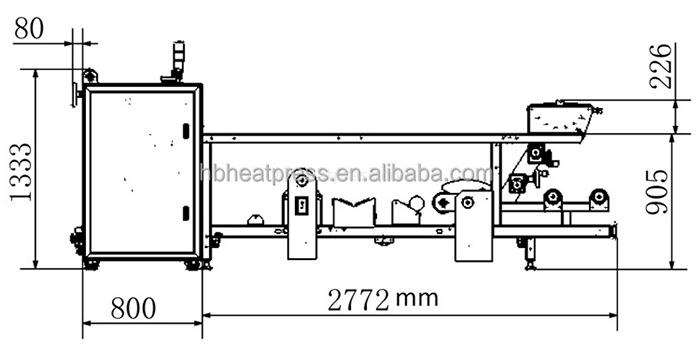

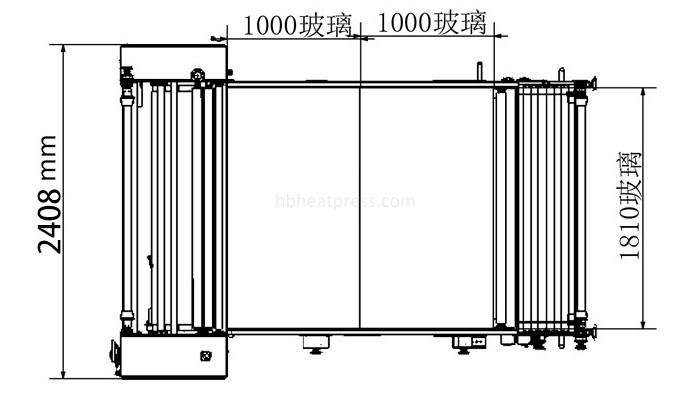

Calendar dimension

Quality control for roll heat press

How to choose a suitable calander sublimation

How to maintain the roll heat press

Contact: Yina Liu

Phone: +8613424008477

Tel: +8613424008477

Email: info@hbheatpress.com

Add: No.1, Lane 1, Liuyang street, Baisha, Zhongluotan, Baiyun district, Guangzhou, China

We chat