Drum type: double-layer chrome-plated Heating type: oil heating Temperature range: 0-260℃ Drum speed: Adjustable Voltage: 220V 3 phase, 380V 3 phase With automatic felt centering system

USD11590-USD12000

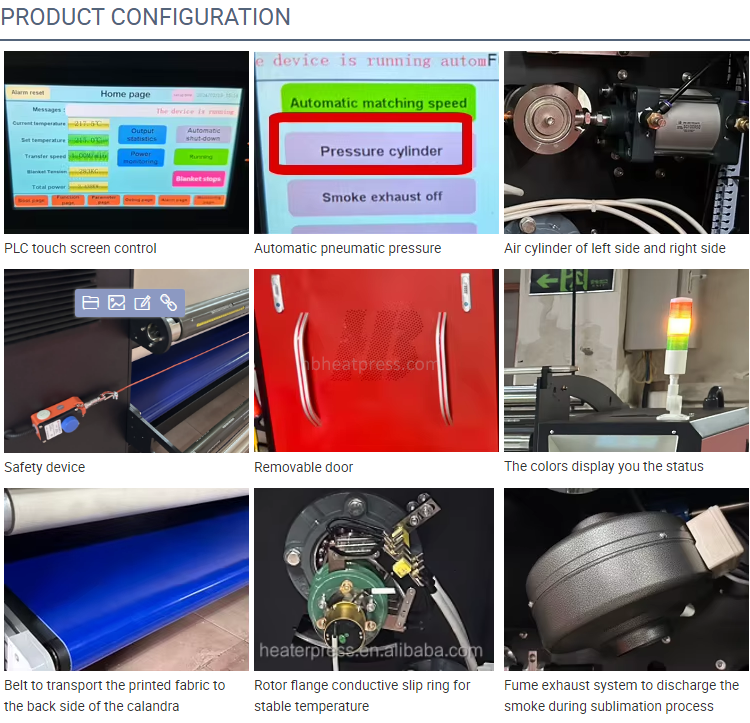

Features

The biggest feature of this sublimation calender is its space saving, which takes up much less space than other 420mm roller diameter machines. Except for loading fabric and paper roll, which requires two people, only one person can do the rest of the work. If the pieces are being transferred, the fabric threading shaft or fabric basket or the automatic feeding system in front of the workbench can be removed, and then the operator stands in the middle of the machine to lay out the pieces.

With fabric rod and fabric feeding system, the fabric rod on the table is for regular fabrics. The feeding system is for stretching fabric like polyester with spandex. The automatic fabric feeding system is equipped with sensors. When the fabric reaches a certain length, the sensors detect it and stops the fabric feeding, thus matching the machine's transfer speed.The fabric feeding system is equipped with a opening roller, which effectively helps open the wrinkles of the fabric and provide a smooth entry.

It features a sensor switch to automatically correct the alignment of the fabric.

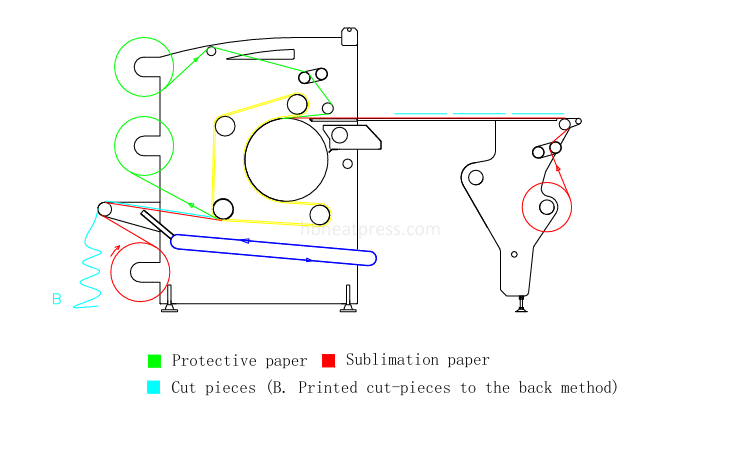

The blue belt is to transport the printed roll fabric or the printed cut pieces to the back side of the machine. The printed fabric can be taken up by the metal rod or by the air shaft.

You can press the "pressure cylinder" on the touch screen if the fabric you are transferring is a thin fabric. It activates the air cylinders, which presses the pressurized shaft against the blanket.

It has two easily removable doors for easy inspection and maintenance of the machine. There is no need to leave much space on the left and right sides of the machine.

The pull-cord switch at the back side of the machine and the emergency stop buttons serve the same purpose. In an emergency, all you have to do is slap the red cord or push pne of the stop buttons, and the blanket will detach from the drum immediately.

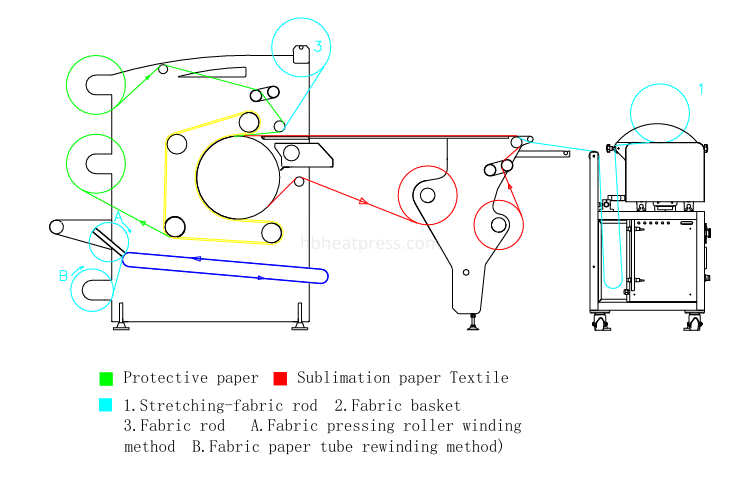

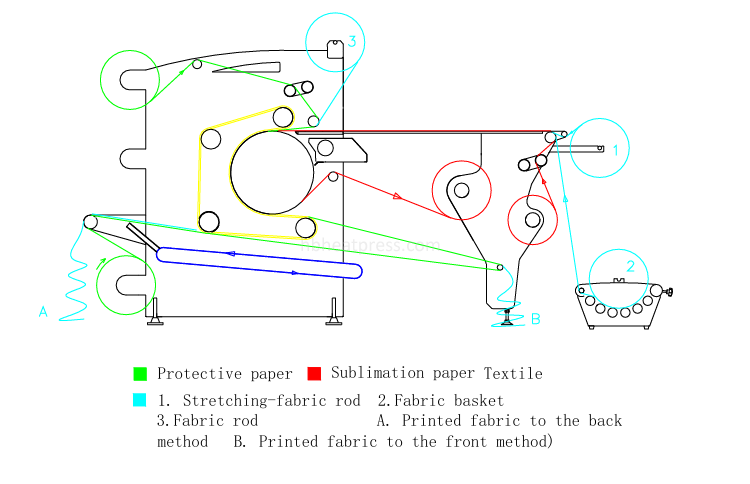

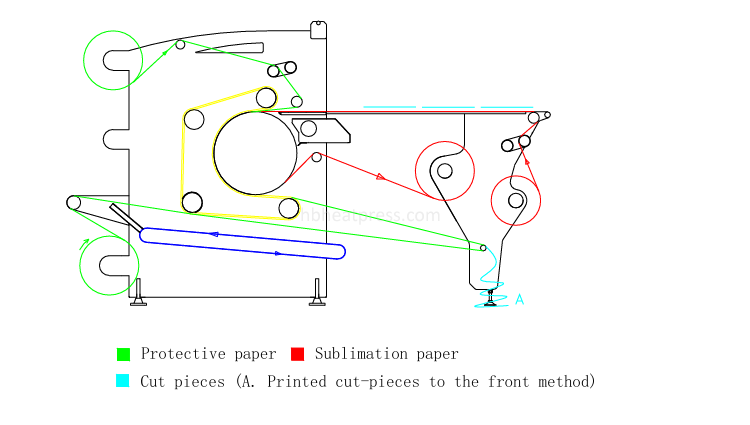

The uniqueness of this machine is that it has some different working modes:

First way, place ordinary non-elastic fabric at the front of the workbench, place it in a fabric basket or load it on a fabric threading shaft.

The sublimation paper is installed on the air-expansion shaft at the front of the workbench, and the other air-expansion shaft on the workbench is used to rewind the used sublimation paper.

The protective paper is placed on the top shaft on the back of the machine, and the second shaft from the top is used to rewind the used protective paper.

After the fabric is transferred, it is transferred to the back of the machine through the blue conveyor belt, and rolled up with a thin metal shaft or an air-inflating shaft.

Second way, load the stretch fabric on the feeding system. Sublimation paper and used sublimation paper are put same as the first way. Protective paper and used protective paper are put same as the first way. Then the sublimated stretch fabric can be taken up the the air shaft after loading a paper tube to the air shaft.

Third way, put sublimation paper and fabric same as first way or second way. Put protective paper on the top air shaft, the lowest air shaft is used for rewinding used protective paper. Leave the printed fabric without rewinding.

Forth way and fifth way are for roll to pieces. The fabric rod on the workbench can be removed. And user can stand in the front of the machine to put cut pieces. The printed cut pieces can be collected in the front or at the back side of the machine.

Technical parameters

Model | HB42P/1850 | ||

Version | PLC Touch screen | ||

Drum type | Chrome-plated drum | ||

Drum diameter | 420mm | ||

Drum width | 1800mm | 2000mm | |

Transferring width | 1650mm | 1850mm | |

Used for | Roll to roll and roll to pieces | ||

Voltage | 380V 3 phase | ||

Preheating Power | 25KW | 28KW | |

Preheating Amperage | 38A | 43A | |

Sublimation speed | Adjustable, mostly using 80-100m/h | ||

Automatic blanket alignment | Yes | ||

Automatic pneumatic pressure | Yes | ||

Automatic shutdown | Yes | ||

With automatic fabric feeding system | Yes | ||

With opening roll | Yes | ||

Blanket tension | Set by touch screen | ||

Air shaft | 4 pieces/5 pieces | ||

Fabric rod | 2 pieces | ||

Fabric basket | Yes | ||

Fume exhaust system | Yes | ||

Net weight | 1594KG | 1794KG | |

Gross weight | 1800KG | 2040KG | |

Packing dimension | 277X131X166cm+ 212X104X78CM | 297X131X166CM+ 232X104X78CM | |

Working flow

Calendar sublimation package

FAQ:

A1: If the printing width is 1,65 m, you can choose the 1,8 m drum width.

A2: Sublimation speed is 80 to 100 meters per hour.

A3: We use the chrome-plated drum. It is more durable, anti-stretching, etc.

A4: Air shaft means it will be inflatable after you charge air for it. Use the air expansion to secure down paper tube instead of screws.

Quality control for roll heat press

How to choose a suitable calander sublimation

How to maintain the roll heat press

Contact: Yina Liu

Phone: +8613424008477

Tel: +8613424008477

Email: info@hbheatpress.com

Add: No.1, Lane 1, Liuyang street, Baisha, Zhongluotan, Baiyun district, Guangzhou, China

We chat