Roller width: 60cm Roller diameter: 21cm Roller type: Chrome-plated Voltage: 220V 1 phase, 220V 3 phase and 380V 3 phase Power: 6KW

Features

This lanyard roller heat press is appropriate for the majority of consumers. Most customers sublimate sportswear and also sell sublimation ribbons, narrow fabric, wristband, etc. In general, they do not require a huge amount of manufacture for ribbons.

Customers who specialize in the ribbon business will find that the speed of this machine is a little slow, and they will typically want a lanyard heat transfer machine with a drum diameter of 42cm or 60cm.

This calendar can transfer both sides simultaneously.

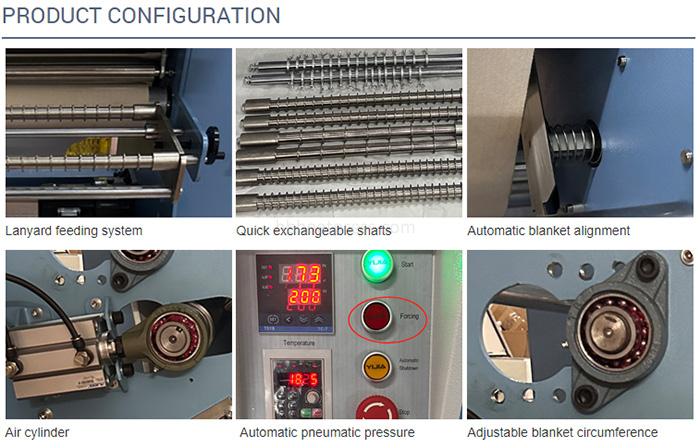

It comes with four sets of metal rods with different interval widths such as 15mm, 20mm, 25mm, and 30mm. It makes them fixed sizes for quick and easy replacement. When you want to sublimate the other size, you can do so swiftly. There is no need to unscrew and tighten them. If you need to sublimate a variety of sizes, we recommend purchasing an additional set of metal rods with adjustable widths.

It is a method of down feeding operation for precise positioning sublimation printing on lanyards.

Function for automatic shutdown. When the temperature drops to 90 degrees, the machine will automatically shut down.

Using oil temperature heating system. Heating with full oil ensures even heating.

The machine is linked to the lanyard winding device on the back side for the 210mm drum diameter. There are two types of shelves for the drum diameter 420mm and 600mm: one that is attached to the machine and one that is separate.

Technical parameters

Roller width | 60cm | 60cm | 90cm | 90cm | 120cm |

Roller diameter | 21cm | 42cm | 60cm | ||

Temperature range | 0-260℃ | ||||

Voltage | 220V 1-phase, 2220V 3-phase, 380V 3-phase | 220V 3-phase, 380V 3-phase | 220V 3-phase, 380V 3-phase | ||

Power | 6KW | 12KW | 17KW | 30KW | 34KW |

Speed (for every single lanyard) | 35-50m/h | 80-100m/h | 160-180m/h | ||

Pressure | Adjustable pneumatic pressure ranges from 0-8kg | ||||

Printing side | Double-sided sublimation printing | ||||

System | Oil heated | ||||

Air compressor | Required | ||||

Net weight | 710kg | 1130KG | 1440KG | 1800KG | 2000KG |

Gross weight | 765kg | 1200KG | 1580KG | 1970KG | 2200KG |

HS code | 8443399000 | ||||

Packing dimension | 142x127x161cm | 196x123x182cm | 196x132x175cm | 215x195x200cm | 229x211x200cm |

Volume | 2.903CBM | 4.388CBM | 4.528CBM | 8.38CBM | 9.66CBM |

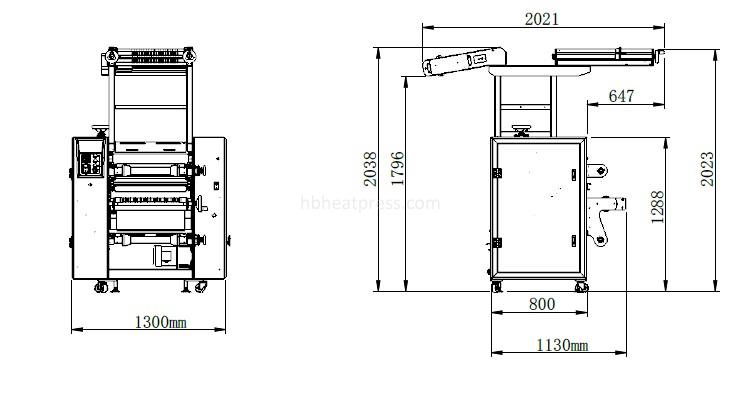

Ribbon calendar dimension for 210x600mm

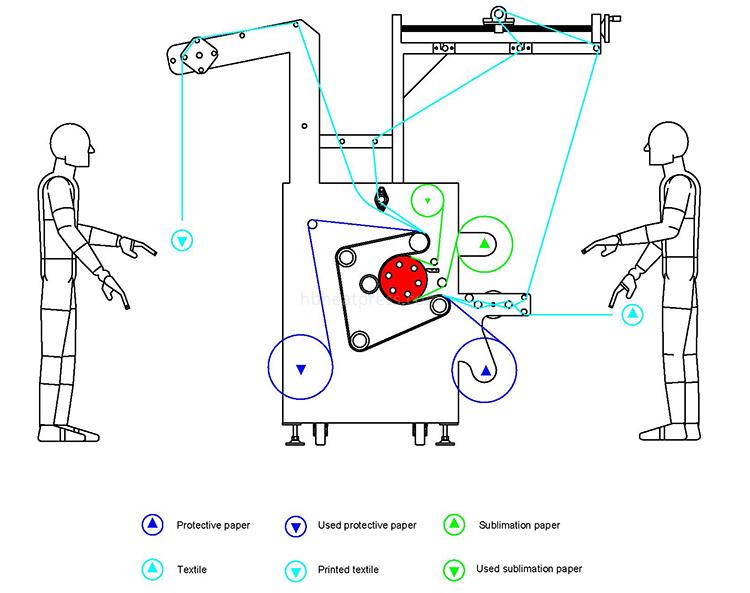

Working flow

FAQ:

Q1:Is it oil heated?

A1: Yes, it is thermal oil heated.

Q2: Do I need an air compressor for the calandra?

A2: Yes, you need it. It has pneumatic pressure function and the air shafts need to be charged air.

Q3: How many meters per hour it can transfer?

A3: Sublimation speed is 35 to 50 meters per hour for every single lanyard. But you can sublimate a few pieces at the same time.

Q4: Why do I need the automatic pneumatic pressure function?

A4: It is perfect for thin ribbon. And with the pneumatic pressure, you can sublimate with higher speed.

Q5: How many pieces of ribbon can I sublimate at the same time for the 60cm drum width calandra?

A5: If you print single side ribbon with 25mm width, you can print 18 pcs. If double side, it will be 9pcs.

Q6: Is the drum surface chrome-plated or coated?

A6: The drum surface is chrome-plated.

Q7: What equipment and materials do I need for using this machine?

A7: You need a sublimation printer, sublimation heat transfer papers, sublimation ink, lanyards and protective papers.

Quality control for roll heat press

How to choose a suitable calander sublimation

How to maintain the roll heat press

Contact: Yina Liu

Phone: +8613424008477

Tel: +8613424008477

Email: info@hbheatpress.com

Add: No.1, Lane 1, Liuyang street, Baisha, Zhongluotan, Baiyun district, Guangzhou, China

We chat