Drum type: double-layer chrome-plated mirror surface Heating type: oil heated Temperature range: 0-260℃ Drum speed: Adjustable Voltage: 220V 3 phase, 380V 3 phase Working mode: roll to roll and roll to pieces

Features

The fabric roller sublimation machine is a high-performance thermal calender specifically engineered for roll-to-roll sublimation of fabrics. With a width of 180 cm, it is designed to handle a wide range of textile materials, ensuring precision and efficiency in the sublimation process. This model combines advanced technology PLC touch screen with a compact design to fit various production environments, from small workshops to larger textile facilities. It can be used for cut panels also.

Precise Temperature Control: Features an advanced temperature control system for accurate heat settings, essential for high-quality prints. The rotor flange conductive slip ring can ensure continuous and stable temperature for long-term use.

Optional collecting ways for printed substrates: The green conveyor belt can move forward and move backward, which allows user to choose the working way. Printed fabric can come to the front and can go to the back of the calander.

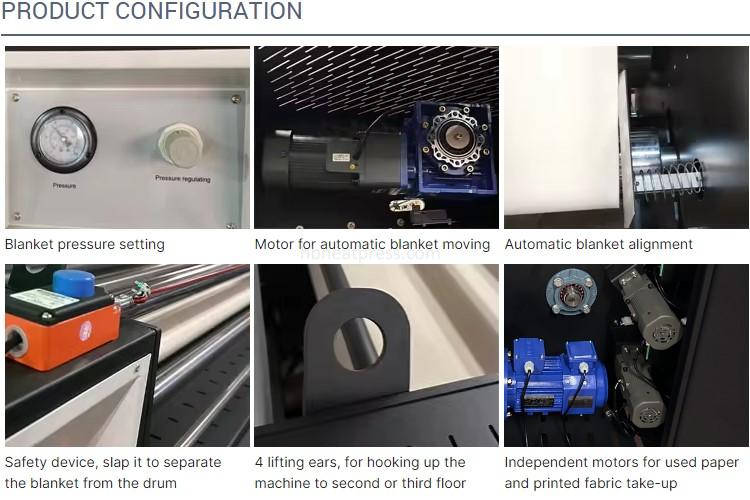

Space-saving deign: Although it is compact, compared with other styles of 420mm diameter oil sublimation calender, it also has all the functions it should have. For example, automatically correct deviation of blanket, automatically pressurizes, and automatically cools down. Optional fabric basket, smoke exhaust system, etc.

Robust Construction: Built with high-quality materials to ensure durability and long-term reliability. For example, the basket required two grown men to lift it.

Easy Maintenance: Designed for easy access to components for straightforward maintenance and servicing.

Emergency Stop Mechanism: Equipped with an emergency stop button and the pull-cord switch ,both are for immediate shutdown in case of any issues.

Technical parameters

Calander sublimation package

FAQ:

A1: If the printing width is 1,6 m, you can choose the 1,8 m drum width.

A2: Sublimation speed is 80 to 100 meters per hour.

A3: We use the chrome-plated drum. It is more durable, anti-stretching, etc.

A4: Air shaft means it will be inflatable after you charge air for it. Use the air expansion to secure down paper tube instead of screws.

Quality control for roll heat press

How to choose a suitable calander sublimation

How to maintain the roll heat press

Contact: Yina Liu

Phone: +8613424008477

Tel: +8613424008477

Email: info@hbheatpress.com

Add: No.1, Lane 1, Liuyang street, Baisha, Zhongluotan, Baiyun district, Guangzhou, China

We chat