Working way: cut pieces to cut pieces sublimation printing Heating method: Oil heating Voltage: 220V 3 phase, 380V 3 phase Function: Automatic substrates feeding in, automatic blanket alignment, etc.

Features

Why are there so many styles of rotary calander heat transfer machines? Because some customers only need to transfer roll paper to roll fabric, some customers only need to transfer roll paper to cut pieces, some customers only need to transfer cut pieces to cut pieces, and some customers need to transfer both roll to roll and roll to piece. Also, due to different usage habits, some customers need to feed materials and then the final materials are discharged from the front of the machine, while some customers require materials to be discharged from the back of the machine, etc.

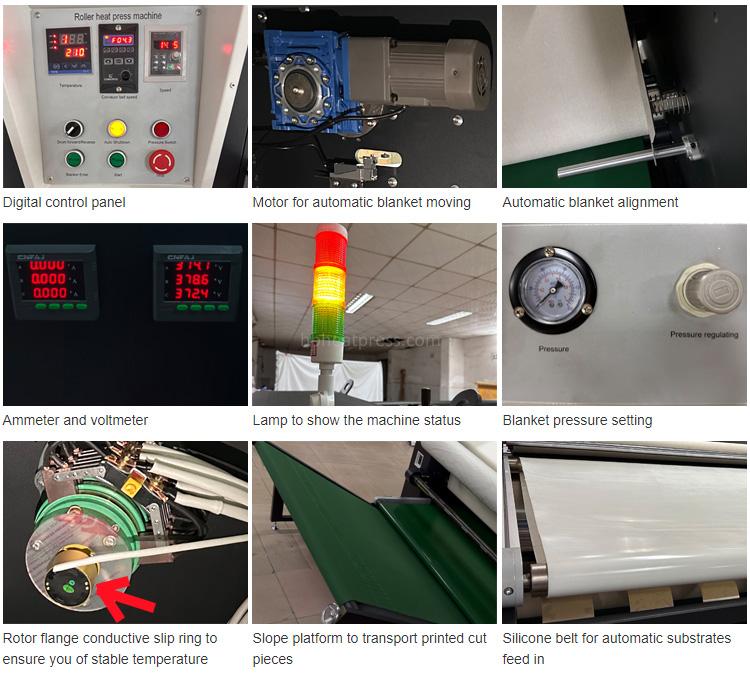

The machine is simple and easy to operate. Press the "blanket enter" button and wait until the blankets are automatically fed.

Then push the "start" button to set the temperature, roller speed, and silicone conveyor belt speed. During the heating process, load the protective paper on the back of the machine.

After the temperature reaches the set value, start feeding the protective paper. Choose whether to turn on pressure according to the thickness of the substrate.

The conveyor belt of the workbench is made of silicone because it is more durable and more resistant to high temperatures than PVC. Because the front part is close to the drum, the PVC material may deform after being used for a period of time.

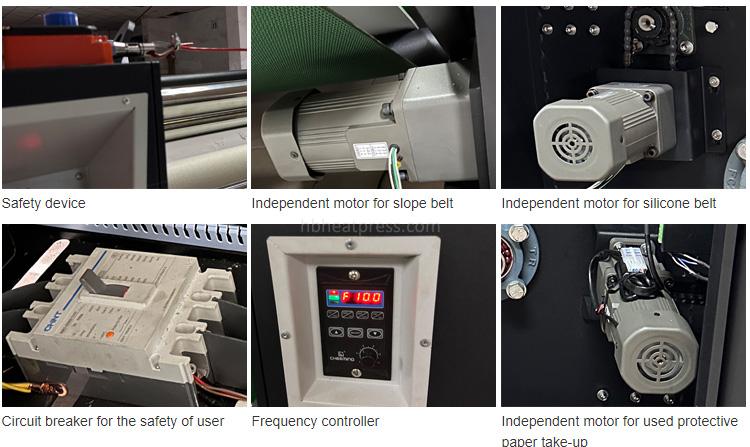

Multiple positions of the machine are controlled by independent motors to avoid being unable to use the machine due to a fault in a certain position in the future, making maintenance easier. And it can make the feed speed easier to adjust. Inclined conveyor belts can increase speed and improve work efficiency.

We have fully considered the safety of users when designing the machine. In addition to installing a pull-cord switch on the main unit, we also installed a leakage protection switch.

Technical parameters

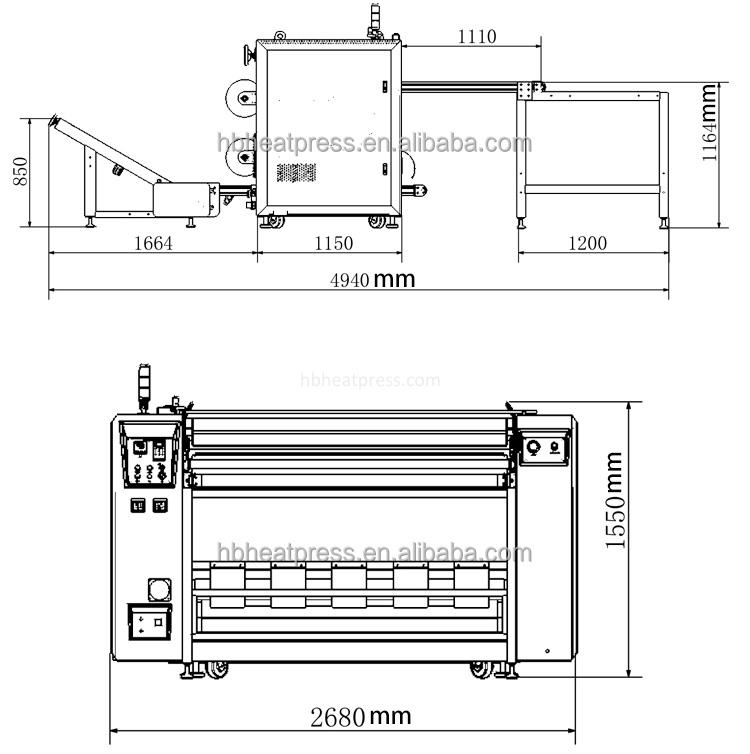

Calandra dimension

Rotary calander transfer package

Quality control for roll heat press

How to choose a suitable calander sublimation

How to maintain the roll heat press

Contact: Yina Liu

Phone: +8613424008477

Tel: +8613424008477

Email: info@hbheatpress.com

Add: No.1, Lane 1, Liuyang street, Baisha, Zhongluotan, Baiyun district, Guangzhou, China

We chat