Make sure the heating plate and lower plate are sufficiently thick if you are able to spend the money on a high-end and heavy-duty heat press equipment. Insufficient thickness increases the likelihood of deformation within a brief period of time. Since heat presses frequently operate at high temperatures, 150–165°C will be used for DTF transfers. Additionally, sublimation will occur at 200–220°C.

A almost 7cm heating plate for our touch screen fully automatic heat press machine may be seen in the first picture below. It has more thickness as compared to other firms.

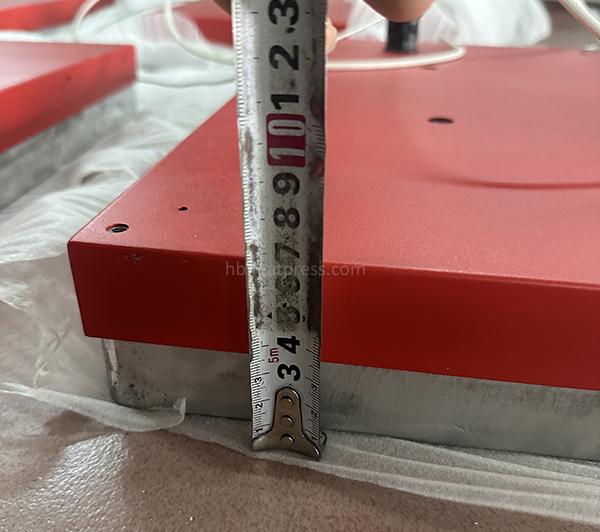

Lower plate is shown in the second image. Additionally, thick material is used.

Not only must we view the thickness, but we also must view the substance. For our heat presses, aluminum is used for both the upper and bottom plates. Some vendors employ iron for the lower plate in order to cut costs and sell their products at a lower price.

It is important to make sure that the surfaces of the heating plate and base plate are sufficiently smooth and flat since the transfer effect is influenced by both their thickness and levelness.

Thus, it's crucial to experiment with dark-colored polyester and sublimation paper patterns. On the heating plate or bottom plate, you can check for any white spots, convex or sunken regions, or other signs of processing issues.

On the other hand, the silicone pad also has an impact. The transfer effect will also be impacted if the silicone pad is composed of low-quality hard silicone with little silicone content.

It is extremely crucial to select an electric or big cylinder substrate when transferring metal, silicone pads, or other comparable materials. To guarantee a successful transfer, they need more pressure.

Quality control for roll heat press

How to choose a suitable calander sublimation

How to maintain the roll heat press

Contact: Yina Liu

Phone: +8613424008477

Tel: +8613424008477

Email: info@hbheatpress.com

Add: No.1, Lane 1, Liuyang street, Baisha, Zhongluotan, Baiyun district, Guangzhou, China

We chat